In recent years, the global woodworking and furniture industry has seen a major shift in production technology. Among these advancements, the Flat Lamination Machine has emerged as a critical tool, widely adopted across furniture factories, construction material workshops, and interior decoration enterprises. Chinese manufacturers, particularly those based in Foshan, have rapidly risen to prominence by offering customized and innovative solutions. Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd., established in 2004, has become one of the leading enterprises driving this transformation with its wide range of Flat Lamination Machines, Semi Automatic Lamination Machines, Automatic Lamination Machines, Cold Glue Lamination Machines, and Semi Automatic Sheet Film Lamination solutions.

Company Profile: Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd.

Located in Lunjiao Town, Shunde, Foshan – known as the “Woodworking Machinery Town of China” – Xingmingda has over 20 years of experience in designing and producing advanced woodworking equipment. Its portfolio includes:

Flat Lamination Machine series for industrial applications

Semi Automatic Lamination Machine for medium-scale factories

Automatic Lamination Machine with intelligent control systems

Cold Glue Lamination Machine for cost-effective eco-friendly production

Semi Automatic Sheet Film Lamination machines for specialized panel work

🌍 Global Recognition: With exports across Asia, Europe, and North America, Xingmingda combines high-quality manufacturing with customer-focused customization.

Industry Trend: Why Flat Lamination Machine Demand is Rising

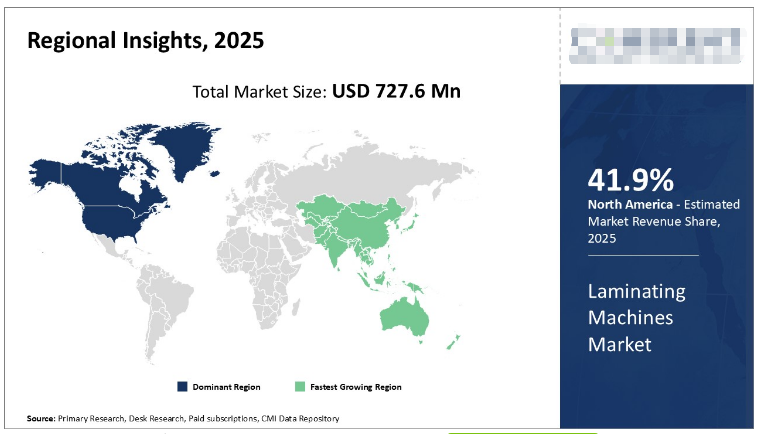

According to recent industry reports:

The global market for Flat Lamination Machines is projected to grow at a CAGR of 7.8% from 2024–2030, reaching USD 3.5 billion.

Semi Automatic Lamination Machines are in high demand for small to medium-scale furniture manufacturers.

Automatic Lamination Machines dominate in large-scale production facilities due to speed and consistency.

Cold Glue Lamination Machines are increasingly preferred for eco-conscious buyers seeking low-emission solutions.

Semi Automatic Sheet Film Lamination is gaining traction in specialized decorative panel production.

Product Highlights

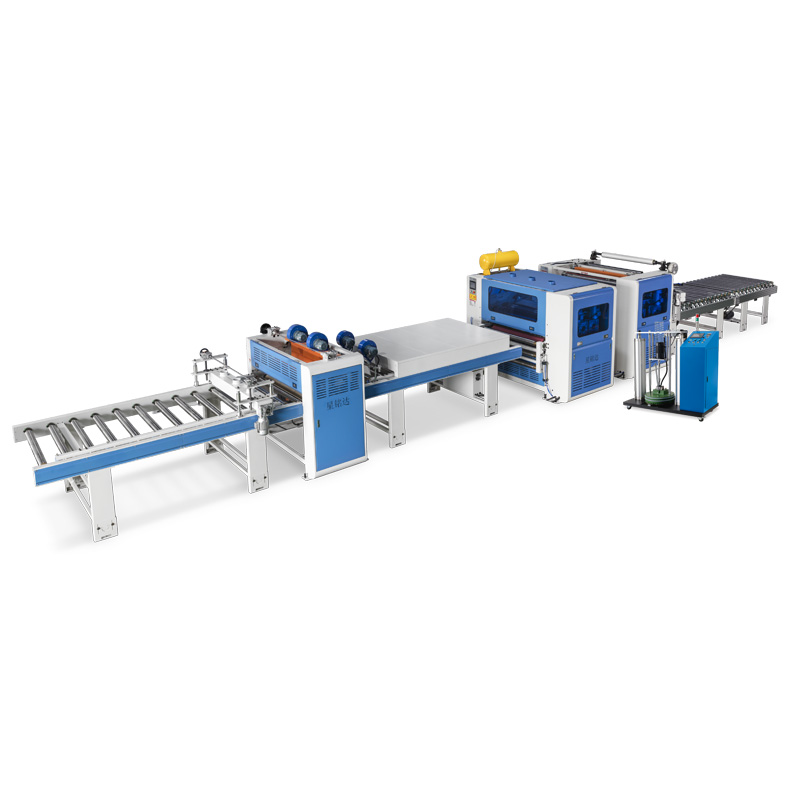

1. Flat Lamination Machine

Provides uniform adhesion for decorative films, PVC, veneer, and laminates.

Widely applied in furniture, wall panels, flooring, and door manufacturing.

High precision ensures long-lasting product performance.

2. Semi Automatic Lamination Machine

Designed for cost-efficient operations in small and medium factories.

Requires less training, easy to operate.

Perfect balance between manual flexibility and machine consistency.

3. Automatic Lamination Machine

Fully automated feeding, gluing, and trimming.

Reduces labor costs by up to 40%.

Capable of handling large-scale production with consistent quality.

4. Cold Glue Lamination Machine

Uses water-based or cold adhesives, reducing energy consumption.

Eco-friendly option for buyers concerned about emissions and chemical safety.

Lower operational cost with minimal maintenance.

5. Semi Automatic Sheet Film Lamination

Specially designed for film-coated sheets and panels.

Popular in custom furniture and decorative board applications.

Offers flexibility in handling different materials.

Semi Automatic Lamination Machine

Automatic Lamination Machine

Cold Glue Lamination Machine

Semi Automatic Sheet Film Lamination

Technical Comparison Table

| Machine Type | Automation Level | Suitable For | Adhesive Type | Key Advantage |

|---|---|---|---|---|

| Flat Lamination Machine | Manual/Semi | General lamination | Hot melt / Cold glue | Versatile applications |

| Semi Automatic Lamination Machine | Semi-auto | Small/medium factories | Hot melt | Cost-effective & flexible |

| Automatic Lamination Machine | Fully auto | Large-scale factories | Hot melt / PUR | High-speed & efficiency |

| Cold Glue Lamination Machine | Semi-auto/Auto | Eco-friendly production | Cold adhesive | Low cost & eco-friendly |

| Semi Automatic Sheet Film Lamination | Semi-auto | Specialized panels | Hot melt | Excellent film adhesion |

Data Report: Global Buyers Preferences

60% of buyers prefer Automatic Lamination Machines for scalability.

25% of small-scale buyers choose Semi Automatic Lamination Machines for affordability.

10% of eco-conscious enterprises are switching to Cold Glue Lamination Machines.

5% niche demand for Semi Automatic Sheet Film Lamination in custom industries.

FAQ – Frequently Asked Questions

Q1: What is the biggest advantage of a Flat Lamination Machine?

👉 It provides stable adhesion across multiple materials, ensuring durability and a smooth finish.

Q2: Is a Semi Automatic Lamination Machine suitable for small furniture factories?

👉 Yes. It’s cost-effective, easy to use, and requires minimal staff training.

Q3: Why should I invest in an Automatic Lamination Machine?

👉 For large-scale operations, it ensures speed, consistency, and reduced labor costs.

Q4: Are Cold Glue Lamination Machines environmentally friendly?

👉 Yes. They use water-based adhesives and reduce energy consumption, making them ideal for green production lines.

Q5: What industries use Semi Automatic Sheet Film Lamination?

👉 It is widely applied in custom furniture, decorative panels, and film-coated sheets production.

Conclusion

The rise of Chinese Flat Lamination Machine manufacturers showcases the global demand for customized, cost-effective, and high-performance solutions. With its strong R&D capacity, advanced management systems, and over two decades of experience, Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd. continues to lead the industry with innovative products such as Flat Lamination Machines, Semi Automatic Lamination Machines, Automatic Lamination Machines, Cold Glue Lamination Machines, and Semi Automatic Sheet Film Lamination solutions.