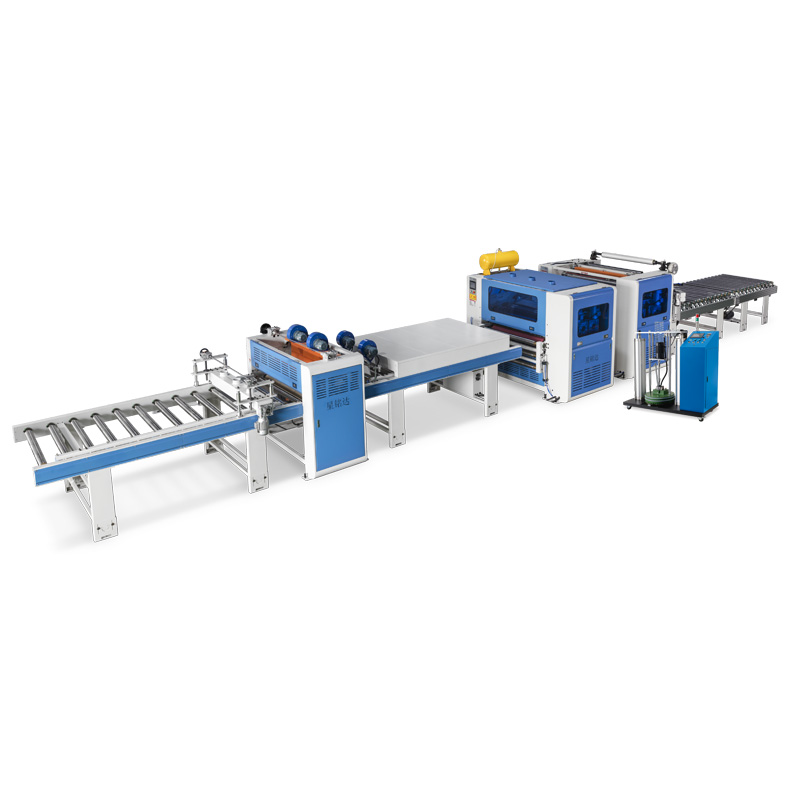

In today’s woodworking industry, PUR Panel Wrapping Machine technology has become an indispensable tool for furniture manufacturers, door producers, and profile wrapping businesses. With the rapid growth of global demand for Wrapping Machine solutions, many international buyers are looking for reliable China PUR Panel Wrapping Machine Manufacturers that can provide both high-quality equipment and customized services.

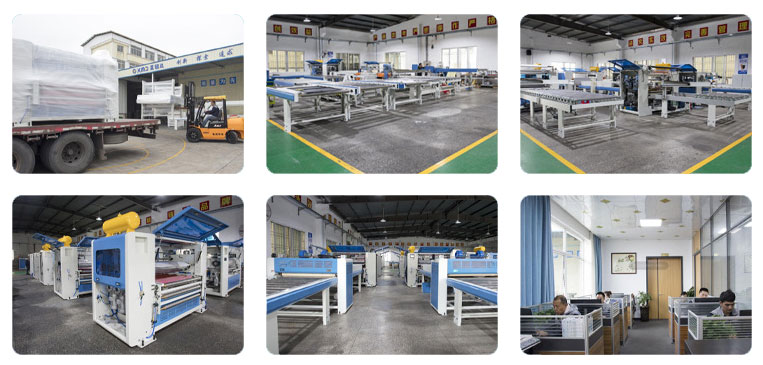

Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd., founded in 2004 in Lunjiao Town, Shunde, Foshan – famously known as the hometown of woodworking machinery in China – is one of the leading manufacturers of PUR Wrapping Machine and PUR Profile Machinesolutions. With more than 20 years of expertise, the company focuses on innovation, efficiency, and customer satisfaction, delivering equipment that meets the evolving needs of the woodworking market.

Why Maintenance of PUR Panel Wrapping Machine Matters?

A PUR Panel Wrapping Machine is a precision-engineered piece of equipment designed to apply PUR hot melt adhesive for wrapping panels, profiles, and boards with decorative films or veneers. Proper maintenance not only extends the service life of the machine but also ensures consistent production quality and reduces downtime.

Neglecting maintenance can lead to:

Poor bonding quality

Glue application problems

Increased energy consumption

Shortened lifespan of critical components

That’s why every operator must learn practical ways to maintain PUR Wrapping Machine and PUR Profile Machine systems.

Practical Maintenance Tips for PUR Panel Wrapping Machine

Regular Cleaning

Always clean the glue system and applicator after production.

Prevent PUR adhesive from solidifying inside the machine.

Check the Glue Tank and Rollers

Inspect rollers for glue build-up.

Ensure even coating to avoid production defects.

Temperature Control

Keep PUR adhesive at the recommended temperature.

Overheating or underheating may damage glue performance.

Lubrication of Moving Parts

Apply industrial lubricant to bearings, gears, and chains regularly.

This prevents wear and tear on PUR Profile Machine components.

Electrical System Inspection

Monitor wiring and sensors.

Ensure the Wrapping Machine operates safely and stably.

Operator Training

Train staff on how to use the PUR Wrapping Machine correctly.

Skilled operators help minimize production waste.

About Foshan Xingmingda – Leading China PUR Panel Wrapping Machine Factory

📍 Company Name: Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd.

📍 Location: Lunjiao Town, Shunde, Foshan, China

📍 Founded: 2004

The company specializes in:

PUR Panel Wrapping Machine

PUR Profile Machine

Edge Banding Machines

Slotting Machines

PUR Hot Glue Laminating Machine

Cold Glue Wrapping Machine

With “high-quality, high-efficiency, innovation” as its core spirit, Xingmingda adopts advanced management systems to stay competitive in the global market.

FAQ – PUR Panel Wrapping Machine

Q1: What is the main advantage of PUR Panel Wrapping Machine compared to traditional glue systems?

A1: The main advantage is stronger bonding strength, heat resistance, and durability. PUR Wrapping Machine ensures long-lasting adhesion compared to EVA glue systems.

Q2: Can Foshan Xingmingda provide customized PUR Profile Machine solutions?

A2: Yes. We specialize in customized Wrapping Machine designs based on customer requirements, including width, speed, and application needs.

Q3: How often should I maintain my PUR Wrapping Machine?

A3: We recommend daily cleaning after production and a complete inspection every 3 months.

Q4: Is technical support available for overseas customers?

A4: Yes. As a professional China PUR Panel Wrapping Machine Supplier, we offer full technical support, training, and after-sales service worldwide.

Q5: Can your factory handle large-volume orders for PUR Panel Wrapping Machines?

A5: Absolutely. As a leading manufacturer, we have the capacity to supply bulk orders with strict quality control.

Conclusion

Maintaining a PUR Panel Wrapping Machine is essential for ensuring long-term performance, production efficiency, and quality consistency. With advanced technology, strong R&D, and 20 years of experience, Foshan Xingmingda stands out as a reliable China PUR Panel Wrapping Machine Manufacturer and Supplier. Whether you need a PUR Profile Machine, Wrapping Machine, or fully customized solutions, Xingmingda provides world-class machinery backed by professional after-sales service.