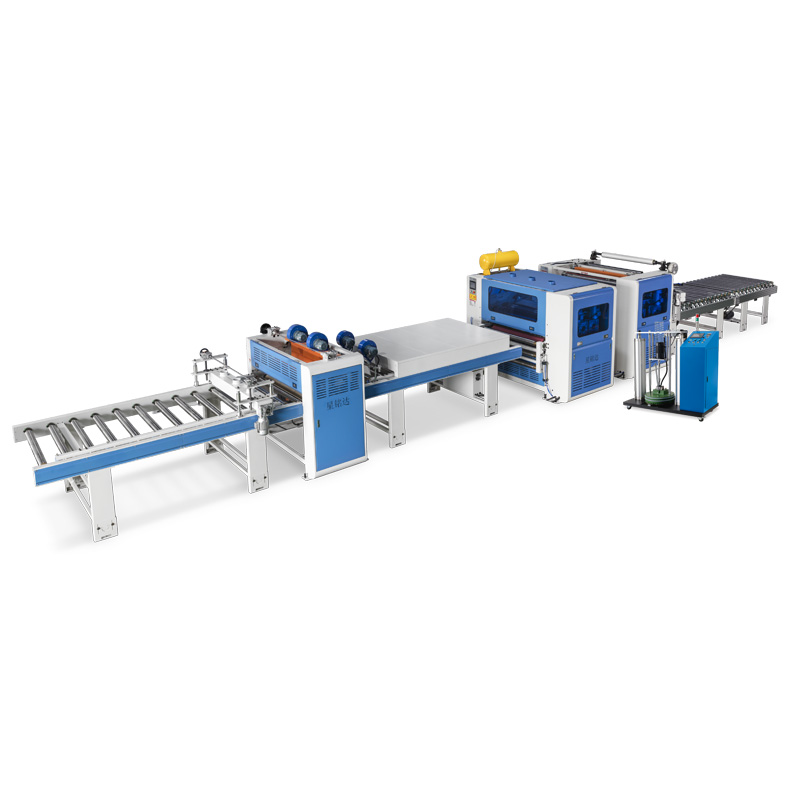

In the woodworking industry, the EDGE banding machine plays a critical role in ensuring the durability, aesthetics, and functionality of furniture products. With the rise of new adhesive technologies, global buyers are increasingly comparing PUR Edge Banding Machines with EVA Edge Banding Machines to determine which solution better fits their production needs. Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd., a leading manufacturer located in Shunde, Foshan – the well-known “Woodworking Machinery Town of China” – is at the forefront of this innovation.

Company Profile: Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd.

Founded in 2004, Foshan Xingmingda has specialized in the design and production of advanced woodworking machinery including edge banding machines, wrapping machines, slotting machines, and PUR lamination machines. With more than 20 years of experience, the company has earned recognition in both domestic and international markets.

🌍 Factory Advantages:

Located in Shunde, the hub of China’s woodworking machinery industry

Advanced R&D and production lines with strict quality control

Rich product portfolio: Edge Banding Machine, PUR wooden edge banding machine, PUR edge banding machine for aluminum, and more

Commitment to “High-Quality, High-Efficiency, and Innovation”

What is an Edge Banding Machine?

Edge Bander is a woodworking machine that applies edge strips to raw board edges, improving aesthetics, durability, and resistance to moisture and damage.

EVA Edge Banding Machine: Uses Ethylene-Vinyl Acetate adhesive.

PUR Edge Banding Machine: Uses Polyurethane Reactive adhesive, offering stronger bonding and durability.

Both technologies are widely used, but they serve different market needs.

Key Differences: PUR vs. EVA Edge Banding Machine

| Feature | EVA Edge Banding Machine | PUR Edge Banding Machine |

|---|---|---|

| Adhesive Type | EVA hot melt adhesive | PUR reactive hot melt adhesive |

| Bonding Strength | Standard, suitable for indoor furniture | Stronger, resistant to heat, moisture, and chemicals |

| Durability | Moderate | Excellent – long-lasting, resistant to aging |

| Application Range | General wooden furniture | Wooden, aluminum, high-gloss, PVC, and complex surfaces |

| Cost | Lower | Higher, but long-term value is greater |

| Eco-Friendly | Basic | More environmentally friendly, low formaldehyde |

✅ Conclusion: For high-end furniture, aluminum profiles, and moisture-prone environments, the PUR Edge Banding Machine is the best choice. For standard, cost-effective production, the EVA Edge Banding Machine remains competitive.

Technical Highlights of Xingmingda Edge Banding Machines

Precision temperature control system for adhesive stability

High-speed automatic feeding and trimming for efficiency

Compatible with multiple materials: wood, PVC, aluminum, and more

Intelligent operation interface, reducing labor cost

Intelligent Operating System

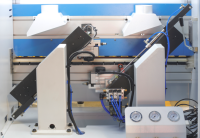

Diamond Cutter Pre Milling Unit

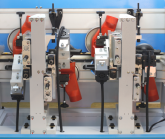

Double Track Front And Rear End Repair

Trimming Unit

FAQ – Frequently Asked Questions

Q1: What is the main advantage of PUR Edge Banding Machine over EVA?

👉 PUR provides stronger bonding, moisture resistance, and is ideal for high-end furniture and aluminum profiles.

Q2: Can the PUR Edge Banding Machine also process wooden furniture?

👉 Yes. It works with wood, PVC, MDF, particleboard, and even aluminum edges.

Q3: Is the investment in PUR machines worth it compared to EVA?

👉 If your market demands durability, premium quality, and export-grade standards, PUR is a must-have choice.

Q4: Do you provide OEM and customization services?

👉 Yes. Foshan Xingmingda offers customized solutions for different production needs.

Final Thoughts

As furniture design evolves and global buyers demand higher quality, the choice between EVA Edge Banding Machine and PUR Edge Banding Machine has become more important than ever. With its strong R&D, advanced technology, and over 20 years of manufacturing expertise, Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd. continues to supply innovative solutions such as the PUR wooden edge banding machine and the PUR edge banding machine for aluminum to buyers worldwide.

👉 For global importers and factory owners seeking durable, efficient, and environmentally friendly solutions, China’s Xingmingda Edge Bander is your trusted partner.