As the global economy faces inflationary pressures and supply chain restructuring, small and medium-sized manufacturing companies around the world face a crossroads: on one hand, rising raw material and labor costs, and on the other, increasingly stringent market demands for product quality and customization. How can they overcome this dilemma? A cost-cutting and efficiency-enhancing revolution centered around automation is becoming a common choice. In this transformation, Foshan Xinmingda Automatic Woodworking Machinery Co., Ltd., a professional PUR Wrapping Machine manufacturer located in Shunde, Foshan, a major woodworking machinery hub in China, is leveraging its deep technical expertise and robust factory-direct supply capabilities to provide global SMEs with the key to a bright future.

A Common Dilemma for SMEs: Costs and Efficiency

For a Spanish cabinet door manufacturer or a Vietnamese furniture exporter, today's operating environment is fraught with challenges. "Skilled workers are becoming increasingly difficult to recruit, wages are rising year by year, and yet our product prices struggle to keep pace." This is a common sentiment shared by many business owners. Furthermore, the trend toward smaller batches and higher-variety orders demands extreme flexibility in production lines. Traditional laminating equipment, however, suffers from high scrap rates due to inefficiency or outdated processes, further eroding already slim profits.

"Customers need more than just a machine; they need a comprehensive solution that addresses their survival and development challenges," a representative from Foshan Xinmingda Automatic Woodworking Machinery Co., Ltd. aptly stated. "This is precisely the motivation behind our development and promotion of a comprehensive line of PUR Wrapping Machines."

A Breakthrough: Cost-Effective PUR Laminating Solutions Made in China

What does cost-effectiveness mean? It's more than simply "low price." Foshan Xinmingda believes that true cost-effectiveness lies in an excellent return on investment (ROI). Their line of PUR Wrapping Machines perfectly embodies this philosophy.

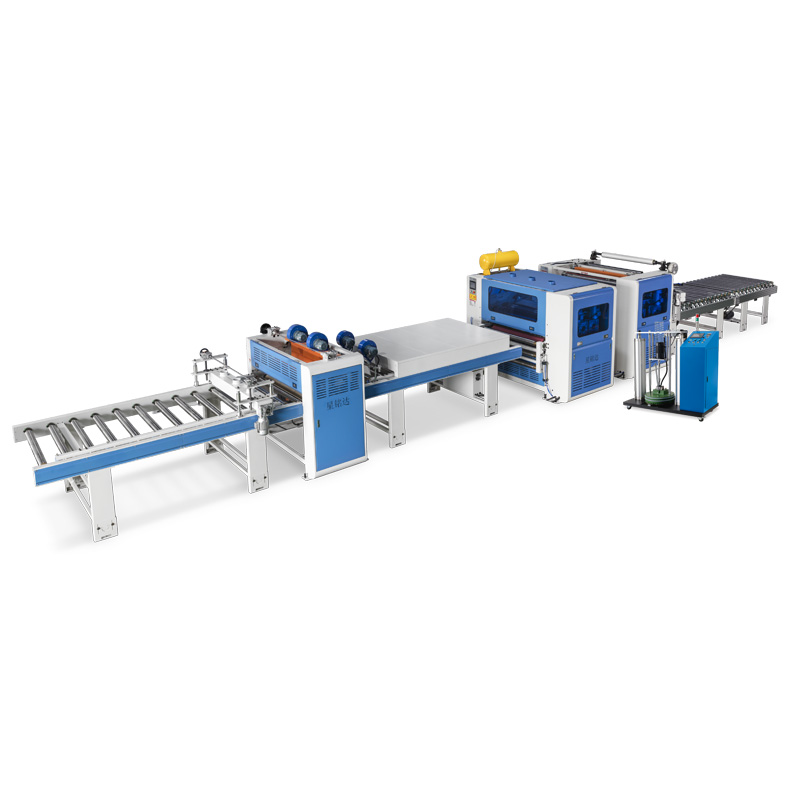

Take their popular 600mm PUR Panel Wrapping Machine, for example. Designed for laminating standard-sized panels, this machine combines efficiency, stability, and ease of operation. The PUR (moisture-reactive polyurethane hot-melt adhesive) technology used is the key to unlocking cost-effective production.

Reducing overall costs, not just procurement costs: "PUR glue forms a strong, irreversible bond after curing. Its high-temperature, solvent, and weather-resistant properties completely eliminate the delamination and warping issues common with traditional EVA glues," explained a technical engineer from Xinmingda. This means that while PUR glue may be slightly more expensive per unit, it requires less application and achieves virtually zero scrap. In the long run, this saves customers significant material loss and after-sales repair costs. This is exactly the long-term economic advantage that small and medium-sized enterprises need.

In addition to solutions for standard panels, Xinmingda has also brought innovations to the processing of custom-shaped materials. Its 300mm Width PUR Profile Machine is a powerful tool for processing narrow workpieces such as moldings and door frames. For manufacturers of skirtings and door and window moldings, this machine perfectly handles complex shapes, achieving seamless, traceless, and high-quality coatings, helping customers easily secure high-end orders.

Another highly anticipated model, the 400mm Width PUR Panel Machine, strikes an excellent balance between flexibility and efficiency. It can handle both medium-sized panels and the edges of some custom-shaped parts, making it ideal for small and medium-sized businesses with diverse product lines and frequent production changes. Its fast mold changeover and machine adjustment capabilities minimize unproductive time.

Supply Chain Advantages: "Wholesale Pricing" and "Customization" Compatible

As a leading manufacturer rooted in the Shunde Industrial Cluster in Foshan, Foshan Xinmingda Automatic Woodworking Machinery Co., Ltd. enjoys a unique supply chain advantage. This enables it to provide high-quality equipment to customers worldwide at highly competitive wholesale prices. However, "wholesale pricing" does not mean "standardization" across the board.

"We deeply understand that every business has unique workshop layouts, product types, and budgets," emphasized Xinmingda's Sales Director. "Therefore, we offer more than just standard machines. For example, customers can choose large, efficient machines like our 1300 PUR Wrapping Machine, or more cost-effective semi-automatic solutions, depending on their production needs. We are committed to tailoring the most suitable PUR Wrapping Machine solution for each customer."

This factory-direct wholesale model, combined with flexible customization services, ensures that customers receive the equipment that best suits their production needs with minimal investment.

In recent years, global inflation and economic uncertainty have created immense pressure on manufacturing enterprises, particularly small and medium-sized enterprises (SMEs). The dual challenges of rising raw material costs and labor shortages have forced many companies to seek new paths toward automation and cost optimization. Against this backdrop, Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd., a professional manufacturer located in the “Town of Woodworking Machinery” — Lunjiao, Shunde, Foshan — is emerging as a trusted partner for global SMEs. With products such as the 600mm PUR Panel Wrapping Machine, 300mm Width PUR Profile Machine, 400mm Width PUR Panel Machine, and 1300 PUR Wrapping Machine, the company provides PUR Wrapping Machines that deliver both efficiency and long-term value.

Global Challenges: Efficiency and Cost Pressure Collide

Across Europe, Southeast Asia, and the Americas, SMEs are navigating a tough business environment: fluctuating orders, limited skilled labor, and intense competition from automation-driven factories. While large enterprises can afford to invest heavily in high-end equipment, SMEs must balance performance, price, and return on investment (ROI) — a balancing act that has never been more critical.

This is where China’s PUR Wrapping Machine manufacturers step in. Far from the outdated notion of “low cost means low quality,” today’s Chinese automation equipment offers a rare combination of technological innovation, stable performance, and affordable pricing, helping global partners achieve efficient and flexible production at reasonable cost.

The Xingmingda Advantage: Cost-Effective Automation, Made in China

Founded in 2004, Foshan Xingmingda has spent over two decades specializing in the research, design, and production of PUR lamination machines, wrapping machines, edge banding machines, and slotting machines. The company’s philosophy — “Quality first, customer satisfaction, continuous innovation” — runs through every stage of manufacturing. From R&D to quality control, Xingmingda integrates precision CNC equipment and adopts advanced management systems to ensure product consistency and durability.

The 600mm PUR Panel Wrapping Machine and 400mm Width PUR Panel Machine have become the company’s star products, designed for high-performance coating and laminating on MDF, PVC, and aluminum profiles. Meanwhile, the 300mm Width PUR Profile Machine and 1300 PUR Wrapping Machine cater to customized panel sizes, allowing clients to achieve both flexibility and productivity. Collectively, these PUR Wrapping Machines help small and medium workshops move toward automation with minimal risk and maximum gain.

High Value ≠ Low Cost — Understanding True ROI

One of the biggest misconceptions about Chinese equipment is that “affordable” equals “cheap.” Xingmingda’s approach challenges this bias. The company emphasizes that high value comes not from cutting corners but from intelligent cost structure — lower waste rates, less downtime, and longer lifespan per machine.

For example, while PUR glue might appear more expensive than traditional adhesives, it has significantly higher bonding strength and requires much less material per use. When combined with Xingmingda’s PUR Wrapping Machine line, it results in smoother finishes, minimal delamination, and far lower scrap rates — a clear cost advantage over time. In many cases, clients have reported recovering their investment within six months of installation.

Flexibility for SMEs: Semi-Automatic and Custom Solutions

Xingmingda understands that not every SME can immediately transition to full automation. Therefore, the company offers scalable solutions — from semi-automatic 300mm Width PUR Profile Machines to fully automated 1300 PUR Wrapping Machines. Each machine can be customized based on the client’s workshop layout, production volume, and product type.

Moreover, the modular design of the 600mm PUR Panel Wrapping Machine and 400mm Width PUR Panel Machine enables easy mold changes and one-click operation. This allows manufacturers to switch between different materials and finishes within minutes — a feature especially valuable for custom furniture producers and architectural panel suppliers who handle diverse orders daily.

Customer Story: From Spain to Success

A vivid example comes from a Spanish cabinet door manufacturer who decided to upgrade from manual lamination to an automated PUR Wrapping Machine system supplied by Xingmingda. Within just six months, the company not only reduced labor costs by 40% but also increased output stability and product consistency. The investment paid for itself faster than expected, demonstrating that small factories can also enjoy the dividends of industrial automation.

Beyond Machinery: Service, Reliability, and Partnership

Behind every machine lies Xingmingda’s commitment to service excellence. The company’s sales and technical network covers domestic and international markets, ensuring timely after-sales support. Regular training programs help enhance staff expertise, reinforcing the belief that “good reputation comes from durable, reliable, and credible quality.”

By combining modern management, skilled craftsmanship, and customer-oriented innovation, Xingmingda has transformed from a local equipment supplier into a global player recognized for dependable PUR Wrapping Machines.

Conclusion: A New Path for Global SMEs

In the age of intelligent manufacturing, the ability to control costs while boosting production efficiency defines competitiveness. For SMEs worldwide, partnering with a Chinese manufacturer like Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd. offers a tangible route toward automation — without overextending budgets.

From the 600mm PUR Panel Wrapping Machine to the 1300 PUR Wrapping Machine, every product represents a commitment to helping enterprises thrive amid uncertainty. In a world where efficiency is survival and innovation is growth, Chinese-made PUR Wrapping Machines are no longer an alternative — they are the solution.