From “Made in China” to “Intelligently Created in China”

Over the past two decades, China’s manufacturing industry has undergone a remarkable evolution—from the “world’s factory” to a global innovation powerhouse. In the furniture and building materials sectors, this transformation has been especially visible. Today, powered by advanced PUR Wrapping Machines, towns like Lunjiao in Shunde, Foshan—known as the “Woodworking Machinery Capital of China”—are quietly redefining the global supply chain.

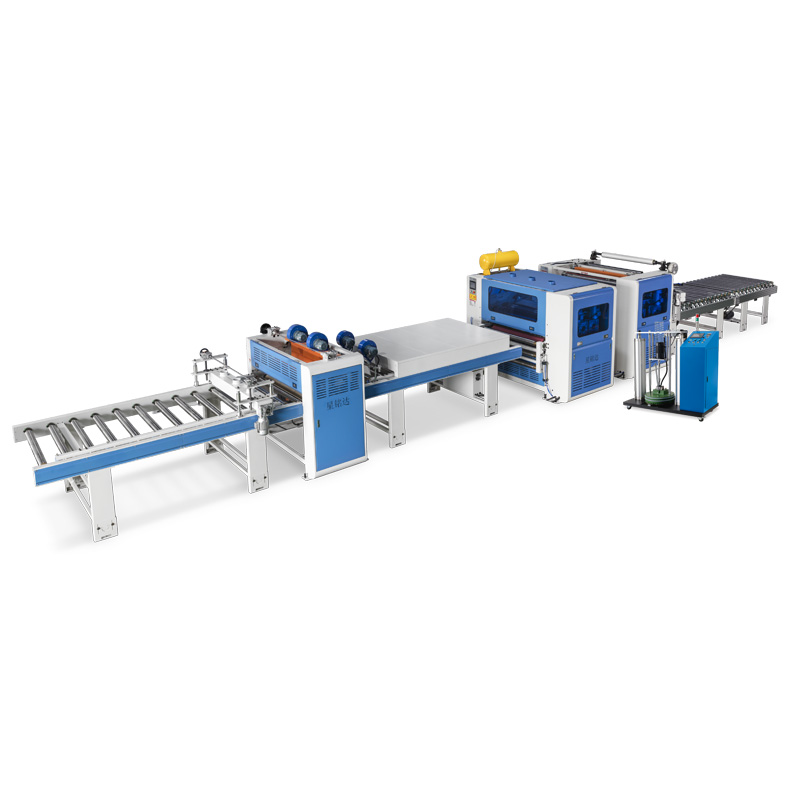

Among these innovators, Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd. stands as a prime example. Established in 2004, the company has grown from producing edge banding and wrapping machines to becoming one of China’s leading developers of PUR lamination technology. Its product lineup—featuring the 600mm PUR Panel Wrapping Machine, 300mm Width PUR Profile Machine, 400mm Width PUR Panel Machine, and 1300 PUR Wrapping Machine—demonstrates how “Made in China” has evolved into “Smart Manufacturing in China.”

I. The Dilemma of Traditional Lamination: Low Efficiency Meets Environmental Pressure

For years, EVA-based lamination dominated the panel finishing industry. Yet, as global demand for durability, aesthetics, and sustainability grows, EVA technology has exposed several weaknesses:

Poor weather resistance – prone to delamination under heat or humidity;

Visible glue lines – reducing surface quality;

High energy use & low automation – unsuitable for modern production lines;

Environmental non-compliance – high VOC emissions violate stricter EU and US regulations.

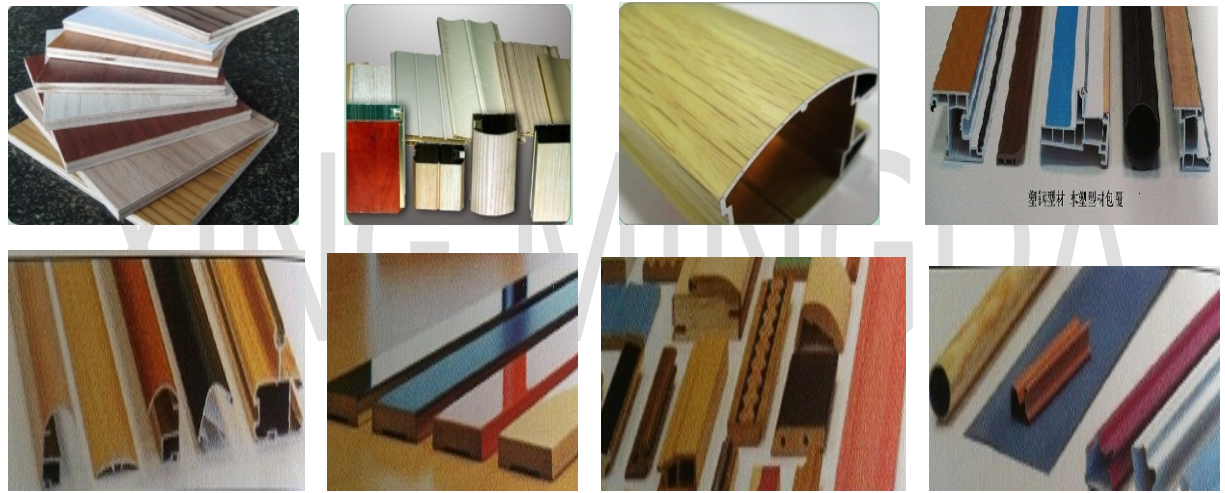

In response, the PUR Wrapping Machine has emerged as a superior alternative. PUR (Reactive Polyurethane Hot Melt) adhesives form a strong molecular bond after curing, offering seamless adhesion, zero emissions, and long-term durability. Beyond performance, PUR technology aligns with global sustainability goals, giving manufacturers both a technical and marketing edge.

II. Technology Breakthroughs: From Mechanical Production to Smart Equipment

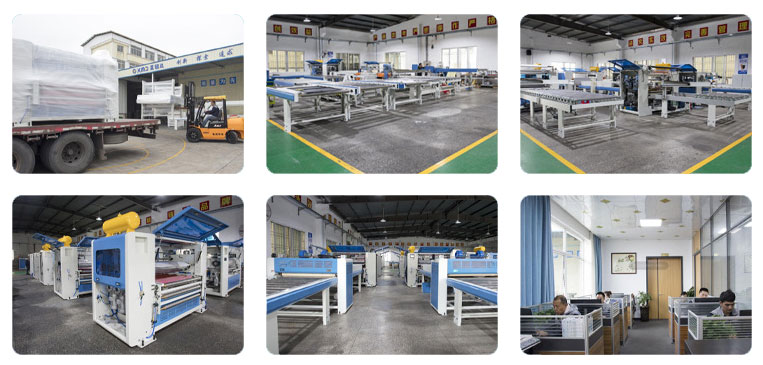

Xingmingda realized early that in order to stand out globally, innovation—not scale—must be the driving force. Located in the heart of Shunde’s woodworking machinery hub, the company built a strong R&D foundation and CNC production capability to create world-class PUR equipment.

The 600mm PUR Panel Wrapping Machine features precision glue-control technology that ensures consistent ultra-thin coating layers, minimizing material waste. The 300mm Width PUR Profile Machine excels in wrapping irregular or decorative profiles, making it ideal for door and window frame applications. The 400mm Width PUR Panel Machine utilizes flexible pressure control to deliver bubble-free, perfectly flat lamination surfaces for high-end furniture manufacturers.

Meanwhile, the flagship 1300 PUR Wrapping Machine integrates seamlessly with automatic feeding and cutting systems, enabling a fully intelligent production line. Manufactured with CNC-machined components and servo-driven control, it achieves lamination precision within ±0.1mm. This leap forward transforms traditional “woodworking machinery” into smart, data-driven production solutions consistent with Industry 4.0 principles.

III. Supply Chain Strength: The Resilience of Chinese Manufacturing

Post-pandemic, global manufacturers are rethinking their sourcing strategies. As companies seek reliability and value, Chinese suppliers are regaining attention for their resilience, capacity, and cost-effectiveness.

Chinese PUR lamination equipment manufacturers offer unmatched advantages:

High capacity – Xingmingda produces hundreds of PUR Wrapping Machines annually for global markets;

Fast delivery – streamlined manufacturing ensures short lead times;

Cost efficiency – machines cost one-third of comparable European brands;

Comprehensive service – technical support includes on-site installation and global remote assistance;

Customization – equipment like the 300mm Width PUR Profile Machine and 400mm Width PUR Panel Machine can be tailored to unique panel sizes, glue formulas, and production speeds.

As a result, the PUR Wrapping Machine family has become the preferred choice for large furniture producers and building material suppliers across Europe, North America, and the Middle East.

IV. Success Stories: From Chinese Workshops to Global Showrooms

A renowned Italian kitchen brand that adopted Xingmingda’s 600mm PUR Panel Wrapping Machine saw production efficiency rise by 30% within three months. The machine’s intelligent temperature control and precise glue application boosted product pass rates to 99%, eliminating the need for manual inspection and reducing labor costs significantly.

In North America, a major door panel manufacturer installed both the 1300 PUR Wrapping Machine and 400mm Width PUR Panel Machine, achieving a fully automated process from substrate to surface finish. The consistent product quality helped the company earn UL certification and expand into the premium construction materials market.

V. Environmental Commitment: Sustainability as a Universal Language

With global carbon neutrality goals accelerating, environmental compliance has become a decisive factor in procurement. Xingmingda’s PUR systems stand out for their solvent-free, low-VOC formulations, and low-temperature curing process that drastically reduces energy consumption.

“Green manufacturing” is not a slogan—it’s a passport to global markets. The company’s PUR Wrapping Machine series includes smart energy-saving modules that automatically adjust power usage, cutting idle electricity consumption by up to 20%. For large-scale factories, this translates into tens of thousands of dollars in annual savings and improved environmental ratings.

VI. Craftsmanship and Culture: Building Reliability Through People

Xingmingda firmly believes that technology innovation must be backed by craftsmanship. The company regularly conducts employee training programs to strengthen team responsibility and foster a “factory-as-family” mindset. From CNC machining to final assembly, every process strictly follows ISO standards.

As the company’s management states, “Good reputation comes from durable, reliable, and credible quality—and that quality comes from passion and precision.”

This spirit of craftsmanship has made equipment such as the 600mm PUR Panel Wrapping Machine, 300mm Width PUR Profile Machine, and 400mm Width PUR Panel Machine synonymous with reliability, helping the brand earn long-term trust from international buyers.

VII. Future Vision: The Global Journey of Chinese PUR Technology

In the next three to five years, the global furniture and building materials industries will move deeper into the era of smart, sustainable manufacturing. Xingmingda plans to integrate AI-based inspection, smart sensors, and remote maintenance into its PUR Wrapping Machine product line—turning it into the digital backbone of next-generation factories.

The company is also collaborating with European partners to develop the next-generation 1300 PUR Wrapping Machine, aimed at achieving higher efficiency and lower energy consumption, setting a new benchmark for global lamination technology.

Conclusion: From Innovation to Global Trust

From a small workshop in Lunjiao to a worldwide service network, Foshan Xingmingda has spent two decades proving that “Made in China” means more than affordability—it means innovation, reliability, and resilience.

As the global supply chain continues to evolve, the PUR Wrapping Machine stands at the heart of technological transformation in furniture and construction manufacturing.

Whether it’s a 600mm PUR Panel Wrapping Machine ensuring precision lamination or a 1300 PUR Wrapping Machine powering intelligent production lines, these advanced machines embody the new face of Chinese Smart Manufacturing—telling the story of how innovation, quality, and trust can reshape the world’s supply chain, one perfectly wrapped panel at a time.