As temperatures drop, woodworking and panel-processing factories often notice an unexpected issue: adhesion quality becomes less stable. Film lifting, weak bonding, or uneven lamination are common winter challenges—but they are not caused by the machine itself. In most cases, the problem lies in unchanged settings that no longer match colder environmental conditions.

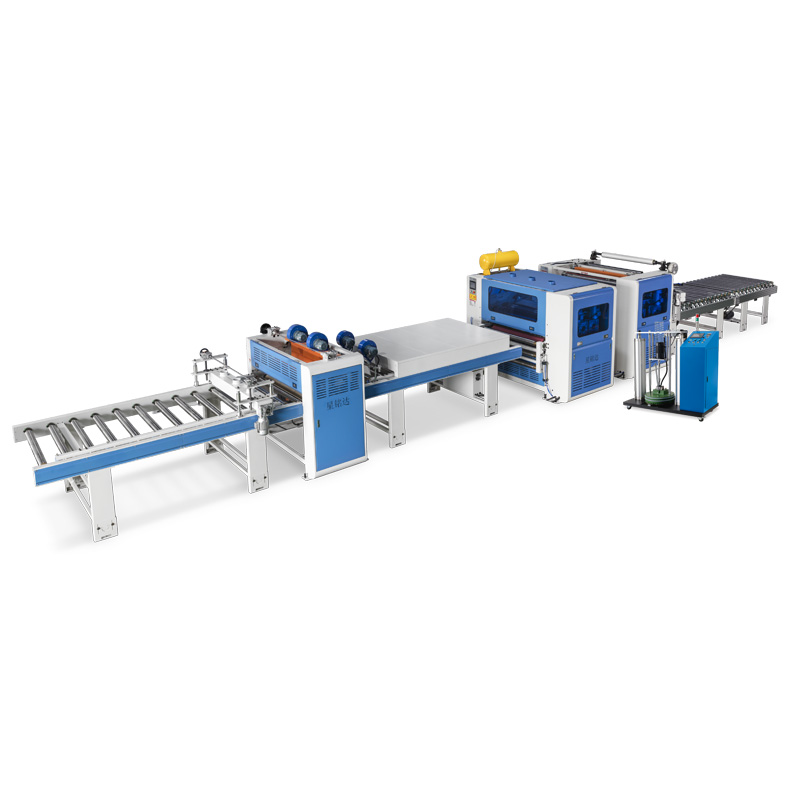

At Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd., we work closely with customers operating a semi-automatic roll film lamination machine, roll film lamination machine, and complete PUR laminating production line. One clear lesson stands out: winter production requires winter settings.

Hello everyone, I’m Sylvia from Foshan Xingmingda. Today, we’ll share practical, proven adjustments that help your Lamination Machine and PUR Lamination Machine line maintain strong adhesion and stable output during cold seasons.

Why Winter Affects Lamination and Wrapping Quality

Lower ambient temperatures reduce surface energy and slow down heat transfer. Boards enter the machine colder, adhesives activate more slowly, and films become stiffer. If settings remain the same as in summer, even a well-designed roll film lamination machine or PUR Lamination Machine line may struggle to deliver consistent bonding strength.

The good news is that only minor adjustments are needed to restore optimal performance.

Winter Settings for Your Lamination Machine

Whether you are using a semi-automatic roll film lamination machine or a fully integrated PUR laminating production line, the principles are the same.

1. Start Pre-Heating Earlier

In winter, always turn on the pre-heating oven earlier than usual. Allow sufficient time for the oven to reach a stable, ideal operating temperature before boards enter the process.

This step is critical for any Lamination Machine, especially when processing thicker panels or dense substrates that absorb heat more slowly.

2. Slightly Reduce Conveyor Speed

Lowering the conveyor speed gives boards more time inside the oven. This allows the panel surface temperature to rise evenly, creating the best condition for adhesive activation.

On a roll film lamination machine, this adjustment improves surface readiness. On a PUR Lamination Machine line, it ensures PUR glue reaches its optimal reaction state.

3. Why These Two Adjustments Work Together

Pre-heating alone is not enough, and speed reduction alone is incomplete. When combined, they significantly improve bonding strength, reduce edge lifting, and stabilize surface quality—especially important for winter operation of a semi-automatic roll film lamination machine.

Winter Settings for Your Wrapping Machine

Wrapping machines face similar challenges in cold environments.

1. Pre-Heating and Speed Control

Just like lamination equipment, wrapping machines benefit from earlier pre-heating and slightly reduced feeding speed. These adjustments help the substrate and film reach a more suitable working temperature.

2. Adjust the Air Gun Film-Blowing Angle

In winter, film rigidity increases. Properly increasing the air gun’s blowing angle helps the film open smoothly and wrap the profile more naturally.

This small change makes a noticeable difference on wrapping systems connected to a PUR laminating production line or operating alongside a Lamination Machine.

Industry Analysis: Seasonal Impact on Lamination Performance

| Parameter | Summer Condition | Winter Condition | Recommended Adjustment |

| Ambient temperature | High & stable | Low & fluctuating | Earlier pre-heating |

| Board surface temperature | Easy to reach | Slower heating | Reduce conveyor speed |

| Adhesive activation | Fast | Delayed | Longer heating time |

| Film flexibility | High | Reduced | Adjust air gun angle |

| Machine stability | Consistent | Sensitive | Fine-tune settings |

These adjustments are especially important for factories operating a PUR Lamination Machine line, where adhesive performance is temperature-sensitive.

Xingmingda’s Experience with Winter Production

Founded in 2004 in Lunjiao Town, Shunde—China’s well-known woodworking machinery hub—Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd. has accumulated extensive experience across climates and markets.

From compact semi-automatic roll film lamination machine models to full-scale PUR laminating production line systems, Xingmingda designs equipment with real-world operating conditions in mind. CNC manufacturing, strict quality control, and continuous technical improvement ensure that every Lamination Machine remains stable, practical, and easy to adjust—even during seasonal changes.

FAQ

Q1: Do winter settings apply to all lamination machines?

Yes. Every Lamination Machine, including the roll film lamination machine and semi-automatic roll film lamination machine, benefits from seasonal adjustment.

Q2: Is it necessary to increase glue amount in winter?

Not usually. Proper pre-heating and speed control are more effective than adding glue.

Q3: Does a PUR laminating production line require longer warm-up time?

Yes. PUR systems need stable temperature to achieve full bonding performance.

Q4: How much should conveyor speed be reduced?

Typically 5–15%, depending on board thickness and ambient temperature.

Q5: Can these adjustments damage productivity?

No. Stable adhesion reduces rework and downtime, improving overall efficiency.

Conclusion

Winter does not have to mean weaker adhesion or unstable quality. With early pre-heating, careful speed adjustment, and small airflow corrections, your semi-automatic roll film lamination machine, roll film lamination machine, and PUR Lamination Machine line can perform just as reliably as in warmer seasons.

These simple changes protect product quality, reduce waste, and extend equipment lifespan—key priorities for every professional PUR laminating production line operator.

Contact Xingmingda

If you need technical guidance, winter-operation advice, or customized solutions for your Lamination Machine or PUR Lamination Machine line, our team is ready to support you.

🌐 Website: https://www.purmachinefactory.com

📧 Email: pattypeng@purmachinefactory.com

Let Xingmingda help your machines work smarter—no matter the season.