As the furniture and decorative panel industry continues to shift toward wider board formats and high-performance surface materials, manufacturers are demanding wrapping equipment that delivers precision, durability, and efficiency. In response to these requirements, Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd. introduces its heavy-duty 1300 PUR Wrapping Machine, purpose-built for boards ranging 600 to 1300 mm in width.

While Xingmingda is widely recognized for its 1300 Wrapping Machine, Cold Glue Wrapping Machine, and 1300mm Cold Glue Wrapping Machine lines, the company’s expertise in wide-format PUR technology further strengthens its position as a leading manufacturer of advanced Wrapping Machine solutions.

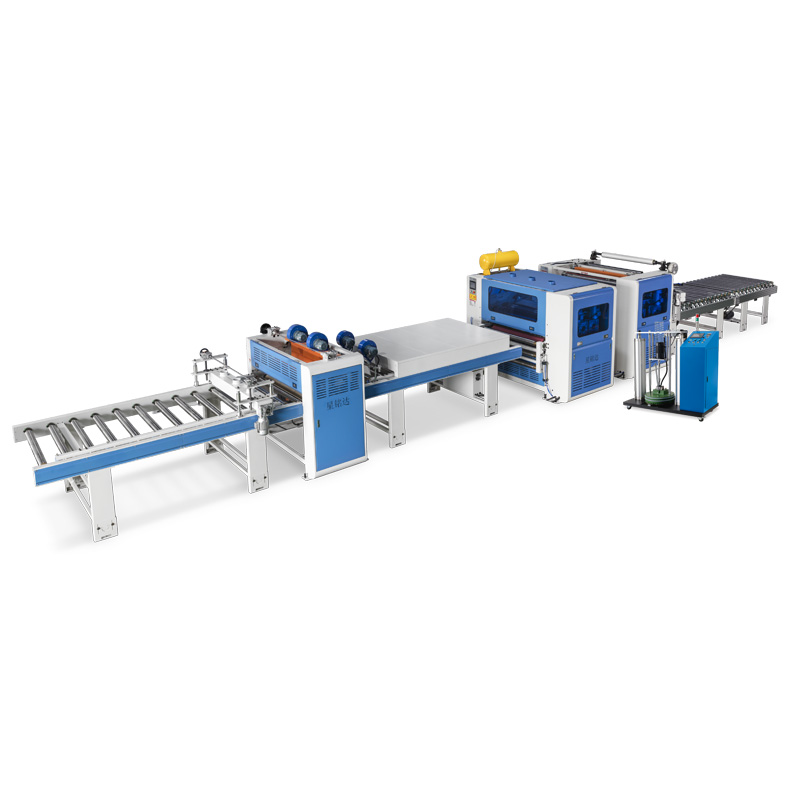

A Four-Part System Designed for Consistent, High-Quality Wrapping

The 1300 PUR Wrapping Machine is engineered as a complete, streamlined production unit consisting of four closely coordinated modules. Each segment contributes to stable feeding, uniform glue distribution, and reliable film bonding across large board surfaces.

1. Input Conveyor

Users can choose between:

Belt conveyor for flexible, quiet material handling

Stainless steel conveyor for heavy-load, long-life industrial use

The conveyor ensures smooth, vibration-free feeding, which is essential when wrapping wide panels that require consistent alignment from the very first stage.

2. Main Wrapping Unit (4 meters)

This is the core component, integrating:

High-precision PUR glue applicator

Film roller system

Premium mold-steel glue knife

The glue knife—precision-machined from high-grade mold steel—is the highlight of this machine. It ensures extremely fine and even glue metering, significantly reducing PUR consumption. Because PUR adhesive is costlier than traditional cold glue, an accurate glue knife can save operators thousands of dollars annually.

The 4-meter body structure offers the stability needed for large-panel wrapping, maintaining consistent pressure and film tension throughout the process.

3. Output Conveyor

As with the input, the output section can be configured as:

Belt conveyor, or

Stainless steel conveyor

This ensures a complete, coordinated transfer from feeding to finished board removal.

4. PUR Glue Tank (200 kg Capacity)

The system uses a 200 kg PUR glue drum, supplying glue to the applicator through a heated glue tube. The PUR is dispensed directly onto the film with exceptional control, ensuring:

Strong bonding

No bubbles

Uniform layer thickness

Long-term durability of wrapped surfaces

PUR is favored for premium applications because it offers heat resistance, water resistance, and superior adhesion to films, veneers, and decorative foils.

Where the 1300 PUR Wrapping Machine Fits in the Industry

With increasing demand for wide decorative boards used in cabinets, wall panels, doors, and large interior components, manufacturers need equipment that handles broad surfaces without sacrificing precision. While the 1300 Wrapping Machine and 1300mm Cold Glue Wrapping Machine are ideal for narrow profiles, the 1300 PUR Wrapping Machine fills the gap for high-volume large-panel production.

Industry Analysis Table

| Category | Trend | Driver | Impact on Wrapping Equipment |

| Wide-format board production | Rapid growth | Cabinet, closet & wall panel industries | Rising adoption of large-width PUR Wrapping Machine |

| Adhesive technology | Shift toward PUR | Durability + heat resistance | More factories upgrading from Cold Glue Wrapping Machine |

| Automation demand | Increasing | Cost efficiency + labor reduction | Stronger demand for conveyor-integrated wrapping lines |

| Material diversity | Expanding | PVC film, high-gloss, veneer | Need for adjustable glue knife and advanced film control |

| Environmental expectations | Growing | Low-VOC & long-life adhesion | PUR systems preferred over common Cold Glue Wrapping Machine systems |

Why Choose Xingmingda’s 1300 PUR Wrapping Machine?

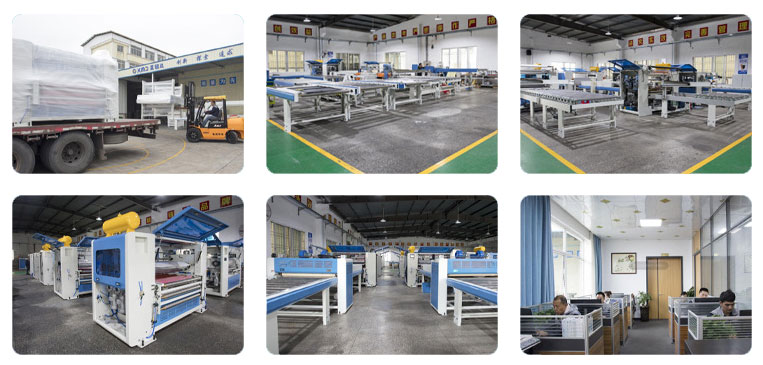

With over 20 years of focus on Wrapping Machine technology, Xingmingda continues to emphasize durability, stability, and operator practicality. The company uses CNC processing equipment, strict quality controls, and high-precision manufacturing, offering customers a solution that is both reliable and competitively priced.

The 1300 model reflects Xingmingda’s engineering philosophy:

Practical operation

Clean bonding and smooth surfaces

Low glue consumption

Strong structural stability

Long service life

A wide-format wrapping machine must be robust, and Xingmingda’s 4-meter PUR unit is designed exactly for demanding industrial conditions.

FAQ

1. What board thickness can the 1300 PUR Wrapping Machine handle?

It supports a wide range, depending on the pressure roller configuration. Most furniture and wall panel substrates fall well within its capacity.

2. Is PUR glue mandatory?

Yes, this model is specifically engineered for PUR application. For cold glue, customers can consider our Cold Glue Wrapping Machine or 1300mm Cold Glue Wrapping Machine options.

3. Does the machine support high-gloss or matte films?

Absolutely. The precision glue knife and stable film roller system handle all common decorative surfaces.

4. How much glue does the machine save?

The mold-steel glue knife applies glue extremely evenly, reducing overuse by up to 20–30% compared with traditional applicators.

5. Can the conveyors be customized?

Yes. Length, width, material, and feeding speed can all be customized according to the production line layout.

Conclusion

The 1300 PUR Wrapping Machine is a robust, wide-format wrapping solution engineered for manufacturers who demand stability, precision, and long-term performance. While the 1300 Wrapping Machine and Cold Glue Wrapping Machine remain essential for smaller profiles, this large-width PUR system offers unmatched efficiency for 600–1300 mm decorative boards.

For factories aiming to upgrade their production line or expand into premium panel wrapping, the 1300 PUR model provides a practical, durable, and cost-effective path forward.

Contact Xingmingda

If you are looking to upgrade your wrapping line—whether for 1300 Wrapping Machine, Cold Glue Wrapping Machine, or wide-format PUR systems—our engineering team will assist you with customized solutions.

🌐 Website: www.purmachinefactory.com

✉ Email: pattypeng@purmachinefactory.com

Tell us your board type, width, and production capacity requirements, and we’ll help you build the wrapping system that fits your factory perfectly.