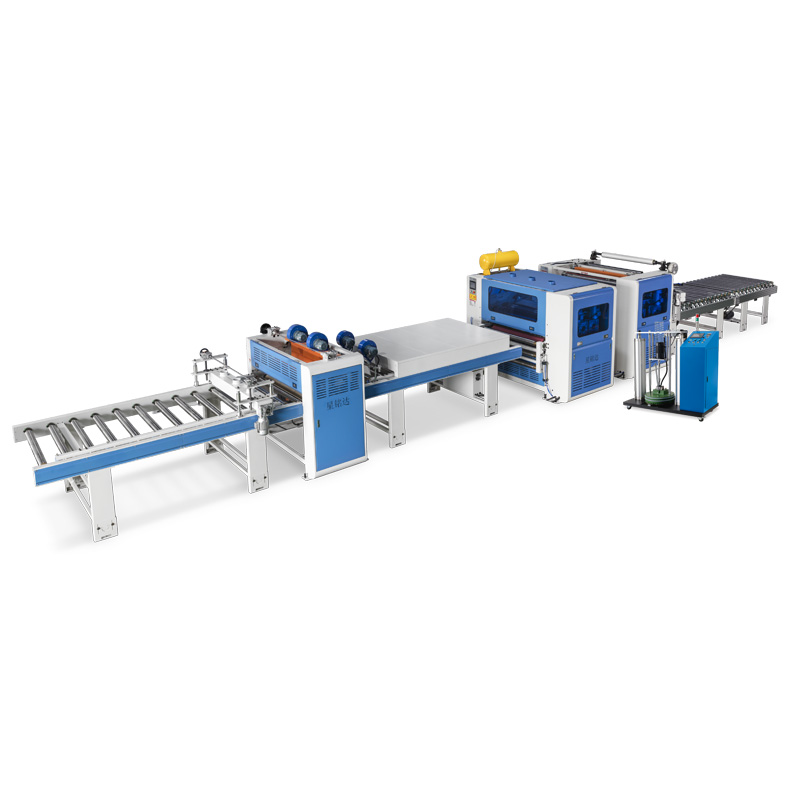

Edge banding machine is a device used for edge banding of boards, usually used in furniture manufacturing and woodworking industries. The correct usage method is crucial for ensuring edge sealing quality and improving work efficiency.

Firstly, before using the edge banding machine, it is necessary to place the board to be edge banding on the workbench and adjust its position. Then turn on the power switch of the edge banding machine and wait for the machine to warm up.

Next, select the appropriate edge banding strip, place it into the feeding port of the edge banding machine, and ensure that the edge banding strip is aligned with the edge of the board. Then start the machine and let the edge banding strip pass through the processing part of the machine to complete the edge banding work.

During the operation, attention should be paid to maintaining the stability of the board to avoid accidents. At the same time, the processing speed and pressure of the machine should be adjusted as needed to achieve the best edge sealing effect.

Finally, after using the edge banding machine, it is necessary to clean the machine in a timely manner, remove residual edge banding strips and sawdust, to ensure the normal operation of the machine and extend its service life.

Overall, the correct usage and maintenance have a significant impact on the working effect and service life of the edge banding machine. I hope the above introduction can help you better use the edge banding machine, improve work efficiency and quality.