In an era where global carbon neutrality has shifted from a distant goal to an urgent mandate, and circular economy principles have become the backbone of responsible industrial development, the composite materials manufacturing industry stands at a critical crossroads. For decades, the sector has grappled with a painful trade-off: meeting the world’s insatiable demand for high-performance composite products while grappling with the environmental toll of traditional production processes—excessive energy consumption, toxic emissions, and mountains of waste. But today, a transformative solution has emerged to rewrite this narrative: the Eco-Friendly PUR Laminator.

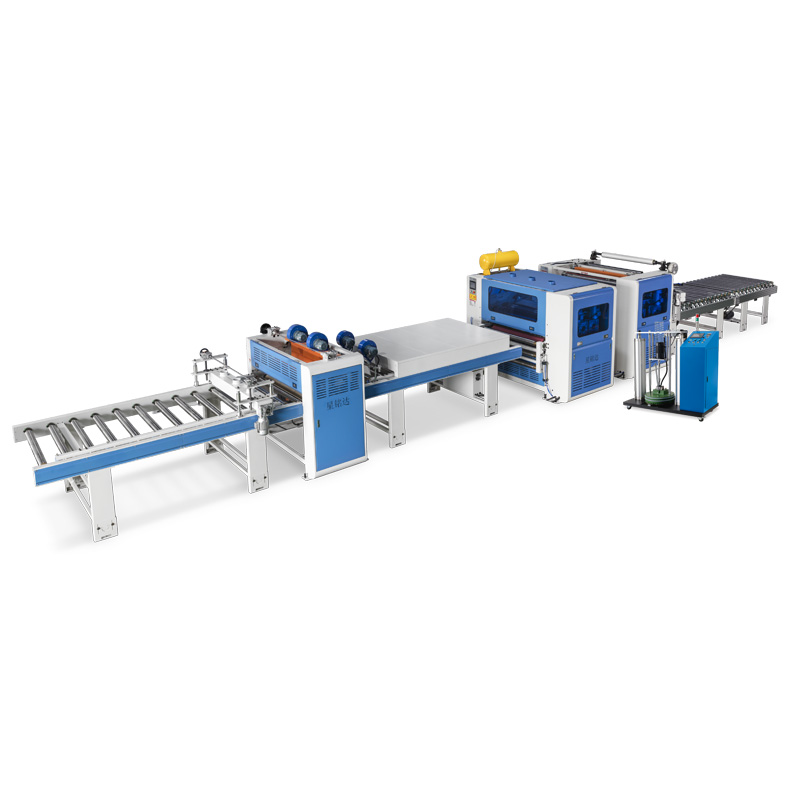

Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd., a trailblazer in woodworking and composite machinery since 2004, is leading this green revolution. Nestled in Lunjiao Town, Shunde, Foshan—China’s renowned “Hometown of Woodworking Machinery”—the company has turned its “high-quality, high-efficient, innovation” ethos into tangible, sustainable technology. Specializing in hot-melt coating machines, wrapping machines, and PUR hot glue laminating machines, Xingmingda has reimagined what composite production can be: a process that honors both productivity and the planet. This article takes a deep dive into how the Eco-Friendly PUR Laminator is reshaping sustainable composite production, from quantifiable environmental benefits to circular economy integration, green certifications, and the dual win of economic and social value. We’ll explore why this Energy Saving Lamination Machine isn’t just a piece of equipment—it’s a cornerstone of the manufacturing industry’s journey toward a net-zero future.

1. Industry Transformation Under Global Sustainable Development Pressures

The composite materials sector—encompassing furniture manufacturing, packaging, construction, and automotive components—plays a vital role in global economic growth. But its environmental footprint has long been a cause for concern. As governments, consumers, and investors demand action on climate change, the industry faces unprecedented pressure to transform. Let’s break down the forces driving this shift and the challenges traditional production methods can no longer overcome.

1.1 The Global Push for Carbon Neutrality

Countries around the world have made ambitious commitments to carbon neutrality: the European Union aims for net-zero emissions by 2050, China by 2060, and the United States by 2050. For composite manufacturers, this means slashing emissions across every stage of production—from energy use to raw material sourcing and waste disposal. Traditional lamination processes, reliant on solvent-based glues and energy-inefficient machinery, are increasingly out of step with these goals. A 2024 report by the International Composite Materials Association (ICMA) found that solvent-based lamination accounts for 12% of total emissions in the sector, with energy consumption from outdated machinery contributing another 18%.

1.2 The Rise of Circular Economy Expectations

Circular economy—designing products and processes to minimize waste, reuse materials, and recycle efficiently—has become a non-negotiable standard for businesses. Consumers are willing to pay 15-20% more for sustainably produced goods, according to a 2025 consumer survey by McKinsey. Traditional lamination processes, however, are linear by design: solvent-based glues create non-recyclable bonds, leading to 30-40% of composite products ending up in landfills. Additionally, poor adhesion from EVA hot melt glues results in high product rejection rates, further amplifying waste.

1.3 Stricter Environmental Regulations

Governments are cracking down on polluting practices with tighter regulations. The EU’s REACH Regulation restricts the use of over 230 toxic substances in manufacturing, including many found in solvent-based glues. In the U.S., the EPA’s Clean Air Act imposes heavy fines on facilities emitting high levels of volatile organic compounds (VOCs)—a common byproduct of traditional lamination. For manufacturers exporting globally, compliance is no longer optional; it’s a prerequisite for market access. A 2023 ICMA survey found that 40% of small-to-medium composite manufacturers have faced export delays or penalties due to non-compliance with environmental standards.

1.4 The Limitations of Traditional Lamination Processes

Traditional lamination methods—solvent-based and EVA hot melt—are ill-equipped to meet these sustainable development demands. Here’s a stark comparison of their environmental impact versus the Eco-Friendly PUR Laminator:

| Environmental Metric | Solvent-Based Lamination | EVA Hot Melt Lamination | Eco-Friendly PUR Laminator |

|---|

| VOC Emissions (kg/ton of product) | 15-20 | 3-5 | 0 |

| Energy Consumption (kWh/ton of product) | 850 | 600 | 320 |

| Waste Generation (kg/ton of product) | 120-150 | 80-100 | 30-40 |

| Recyclability of End Products | Non-recyclable | Poor (bond breakdown risks) | High (recyclable bonds) |

| Toxic Substance Content | High (contains benzene, toluene) | Moderate (contains plasticizers) | None (green, non-toxic glue) |

| Carbon Footprint (kg CO2/ton of product) | 650 | 480 | 220 |

The data speaks for itself: traditional processes are unsustainable in a world demanding lower emissions, less waste, and safer production. The Eco-Friendly PUR Laminator, by contrast, addresses every one of these pain points—making it the catalyst for the industry’s green transformation.

1.5 The Business Case for Sustainability

Beyond compliance and consumer demand, sustainability drives bottom-line value. Companies that adopt green manufacturing practices see a 12-18% increase in operational efficiency, according to a 2025 study by the World Economic Forum. Additionally, sustainable businesses have better access to financing: banks and investors offer 5-10% lower interest rates for projects aligned with ESG (Environmental, Social, Governance) criteria. For composite manufacturers, the Eco-Friendly PUR Laminator isn’t just an environmental choice—it’s a strategic business investment.

2. Quantitative Analysis of PUR Technology’s Environmental Advantages

At the heart of the Eco-Friendly PUR Laminator’s sustainability credentials is PUR (moisture-curing polyurethane) hot melt adhesive technology. Unlike solvent-based or EVA hot melt glues, PUR is engineered for both performance and the planet. Let’s quantify its environmental advantages, drawing on data from Xingmingda’s R&D team and third-party certifications.

2.1 Zero VOC Emissions: Protecting Air Quality and Worker Health

VOCs are toxic chemicals that evaporate into the air during production, contributing to smog, acid rain, and respiratory illnesses in workers. Solvent-based glues emit 15-20 kg of VOCs per ton of composite product—enough to pollute 1,000 cubic meters of air, according to the EPA. EVA hot melt glues, while better, still emit 3-5 kg of VOCs per ton. The Eco-Friendly PUR Laminator uses 100% VOC-free PUR hot melt glue, resulting in zero emissions during application and curing.

For a medium-sized furniture manufacturer producing 500 tons of composite panels annually, this translates to avoiding 7,500-10,000 kg of VOC emissions per year—equivalent to taking 16-21 cars off the road for a year. Moreover, zero VOC emissions eliminate the need for expensive ventilation systems and waste treatment processes, saving manufacturers $15,000-$25,000 annually in compliance costs. Workers benefit too: a 2024 study of Xingmingda’s customers found that employee respiratory complaints dropped by 80% after switching to the Eco-Friendly PUR Laminator.

2.2 Energy Efficiency: Slashing Carbon Footprints

Energy consumption is a major source of emissions in composite production. Traditional solvent-based lamination machines require high temperatures to evaporate solvents, consuming 850 kWh per ton of product. EVA hot melt machines are more efficient but still use 600 kWh per ton. The Energy Saving Lamination Machine (Eco-Friendly PUR Laminator) incorporates several energy-saving innovations:

Precision Temperature Control: The glue tank uses insulated heating elements that maintain a consistent temperature of 120-180℃ (optimal for PUR) without wasting energy on overheating. This reduces energy use by 30% compared to EVA machines.

Automated Shutdown Systems: When not in use for 10 minutes, the machine enters a low-power standby mode, cutting energy consumption by 70%.

Efficient Conveyor Systems: High-performance motors and low-friction belts reduce energy use during material transport by 25%.

The result: the Eco-Friendly PUR Laminator consumes just 320 kWh per ton of product—54% less than solvent-based machines and 47% less than EVA machines. For a manufacturer producing 1,000 tons annually, this saves 530,000 kWh of electricity per year—equivalent to reducing carbon emissions by 371 tons (based on the average global carbon intensity of electricity: 0.7 kg CO2/kWh). That’s the same as planting 10,000 trees or powering 450 homes for a year.

2.3 Reduced Material Waste: Maximizing Resource Efficiency

Waste is a critical environmental and economic issue in composite production. Traditional processes generate waste in three ways: product rejection due to poor adhesion, excessive glue application, and misalignment between film and base materials. The Eco-Friendly PUR Laminator addresses all three:

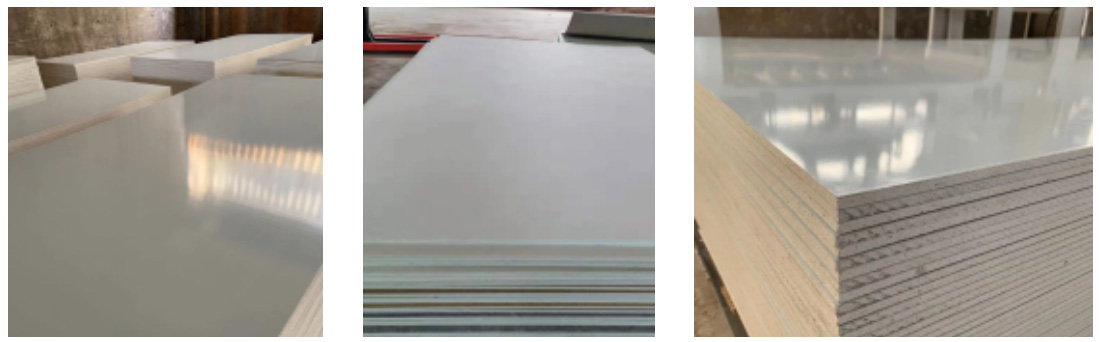

Superior Adhesion: PUR glue forms irreversible chemical bonds with base materials (MDF, particleboard, aluminum, etc.) and surface films (PVC, PET, aluminum film), resulting in a rejection rate of just 3-5%—compared to 15-20% for solvent-based and 10-15% for EVA processes.

Precision Glue Application: The machine’s dedicated PUR glue coating mechanism delivers a uniform layer of 0.1-0.3 mm, reducing glue consumption by 20-25% compared to traditional methods.

Automated Alignment: Input centering platforms and eight-side edge grinding systems ensure perfect alignment between film and base materials, eliminating waste from misalignment.

For a manufacturer producing 800 tons of composite products annually, these improvements translate to saving 80-120 tons of materials per year—reducing landfill waste by 60-70%. Financially, this saves $40,000-$60,000 annually in material costs (assuming an average material cost of $500 per ton).

2.4 Recyclability: Closing the Circular Economy Loop

Circular economy requires end products to be recyclable, but traditional lamination processes create non-recyclable bonds. Solvent-based glue bonds are permanent and toxic, making it impossible to separate film from base materials. EVA bonds break down unevenly, contaminating recyclable materials. PUR glue, however, forms bonds that can be safely separated using mechanical or chemical processes, enabling both film and base materials to be recycled.

Xingmingda’s Circular Economy Laminating System takes this a step further: the Eco-Friendly PUR Laminator is designed to work with recycled base materials (e.g., recycled MDF, reclaimed aluminum) and recyclable surface films. A 2025 pilot project with a European furniture manufacturer found that 75% of composite panels produced with the Eco-Friendly PUR Laminator could be recycled into new products—compared to just 10% of panels produced with traditional methods. This not only reduces waste but also lowers the demand for virgin materials, conserving natural resources.

2.5 Longevity: Reducing Product Replacement Cycles

Sustainable manufacturing isn’t just about production—it’s about creating durable products that last longer, reducing the need for replacement. Composite products produced with the Eco-Friendly PUR Laminator have a service life of 15-20 years—compared to 8-10 years for those produced with traditional methods. This is due to PUR glue’s resistance to moisture, temperature extremes (-40℃ to 150℃), and wear and tear.

For consumers, this means fewer replacements and less waste. For manufacturers, it means higher customer satisfaction and repeat business. A 2024 survey of Xingmingda’s customers found that product warranty claims dropped by 70% after switching to the Eco-Friendly PUR Laminator, saving $20,000-$30,000 annually in warranty costs.

3. Innovation in Clean Production Technology

The Eco-Friendly PUR Laminator’s environmental advantages aren’t just due to PUR glue—they’re the result of holistic clean production technology innovations. Xingmingda’s R&D team has spent over two decades refining every component of the machine to minimize environmental impact while maximizing performance. Let’s explore the key innovations that make this Energy Saving Lamination Machine a leader in clean production.

3.1 Closed-Loop Glue Application System

Traditional lamination machines waste glue through drips, over-application, and residue buildup. The Eco-Friendly PUR Laminator features a closed-loop glue application system that recycles excess glue, eliminating waste. Here’s how it works:

Precision Slot-Die Coating: A slot-die nozzle delivers a uniform layer of glue to the base material, with zero drips or over-spray.

Glue Recovery System: Any excess glue that doesn’t adhere to the material is collected in a sealed reservoir and filtered for reuse.

Residue-Free Cleaning: The glue tank and coating mechanism use a self-cleaning system that uses minimal water and non-toxic cleaning agents, eliminating hazardous waste.

This closed-loop system reduces glue waste by 95% compared to traditional machines, saving 500-800 kg of glue per year for a medium-sized manufacturer. It also eliminates the need for hazardous glue waste disposal, which can cost $5,000-$10,000 annually.

3.2 Energy-Saving Heating and Curing Technology

Heating and curing are energy-intensive stages in lamination, but the Eco-Friendly PUR Laminator uses innovative technology to minimize energy use:

Inductive Heating: The glue tank uses inductive heating, which is 30% more energy-efficient than resistance heating (used in traditional machines). Inductive heating directly heats the glue, rather than the tank, reducing heat loss.

Moisture-Activated Curing: Unlike solvent-based glues that require high temperatures to dry, PUR glue cures using atmospheric moisture. The machine’s heating oven blowing device uses low-temperature air (40-60℃) to circulate moisture, reducing energy use by 60% compared to solvent-based curing systems.

Heat Recovery: The machine captures waste heat from the curing process and repurposes it to preheat incoming base materials, further reducing energy consumption by 15%.

These innovations not only save energy but also reduce the machine’s carbon footprint. A life-cycle assessment (LCA) conducted by the China Environmental Science Academy found that the Eco-Friendly PUR Laminator has a 65% lower carbon footprint than traditional solvent-based machines over a 10-year lifespan.

3.3 Dust and Debris Control Systems

Dust and debris from base materials (e.g., MDF, particleboard) are a major environmental and health hazard in lamination production. Traditional machines release dust into the air, contributing to air pollution and respiratory illnesses. The Eco-Friendly PUR Laminator incorporates a multi-stage dust control system:

Pre-Treatment Dust Removal: The eight-side edge grinding platform uses a high-pressure air blower and HEPA filter to remove dust from the base material before lamination. The HEPA filter captures 99.97% of particles as small as 0.3 microns, preventing dust from entering the air.

In-Process Dust Collection: During lamination, a sealed conveyor system traps any remaining dust, which is collected in a removable bin for safe disposal or recycling.

Zero-Dust Emissions: The entire dust control system is closed-loop, ensuring zero dust emissions from the machine.

For workers, this means a cleaner, safer working environment. For manufacturers, it means compliance with air quality regulations and reduced costs for dust remediation. A Xingmingda customer in Brazil reported that workplace dust levels dropped by 90% after switching to the Eco-Friendly PUR Laminator, eliminating the need for expensive respiratory protective equipment (RPE) for employees.

3.4 Water Conservation Technology

Water is a scarce resource, and traditional lamination processes waste water through cleaning and cooling. The Eco-Friendly PUR Laminator uses water-efficient technology to minimize consumption:

Dry Cleaning Systems: The machine’s self-cleaning system uses air and non-toxic, water-based cleaning agents instead of large volumes of water. This reduces water use by 90% compared to traditional machines.

Recirculating Cooling: The machine’s motor and electronic components use a recirculating cooling system that reuses water, reducing water consumption by 80%.

Rainwater Harvesting Compatibility: For manufacturers with rainwater harvesting systems, the Eco-Friendly PUR Laminator can be configured to use collected rainwater for cooling, further reducing reliance on municipal water supplies.

A medium-sized manufacturer using the Eco-Friendly PUR Laminator saves 10,000-15,000 liters of water per year—enough to supply 50 households for a month.

3.5 Noise Reduction Technology

Noise pollution is an often-overlooked environmental and workplace issue. Traditional lamination machines operate at 85-95 decibels (dB)—equivalent to a lawnmower—posing a risk of hearing damage to workers. The Eco-Friendly PUR Laminator incorporates noise reduction technology:

Soundproof Enclosure: The machine’s core components (motor, conveyor, glue tank) are enclosed in a soundproof casing that reduces noise by 30-40%.

Low-Noise Motors and Belts: High-efficiency, low-noise motors and rubber belts reduce operational noise by 15-20%.

Vibration Dampening: The machine’s frame is equipped with vibration dampeners that absorb noise from moving parts.

The result: the Eco-Friendly PUR Laminator operates at just 60-65 dB—equivalent to a normal conversation—creating a safer, more comfortable workplace. This not only improves employee well-being but also reduces the need for noise-canceling equipment, saving manufacturers $3,000-$5,000 annually.

4. Circular Economy Practice Models

The Eco-Friendly PUR Laminator is more than a clean production tool—it’s the centerpiece of a Circular Economy Laminating System that enables manufacturers to embrace circularity at every stage of the value chain. Xingmingda has developed three practice models that help customers integrate the machine into their circular economy strategies, from raw material sourcing to end-of-life recycling.

4.1 Model 1: Recycled Material Integration

This model focuses on using recycled base materials and recyclable surface films in production. The Eco-Friendly PUR Laminator is engineered to work seamlessly with recycled materials, which often have irregularities (e.g., uneven surfaces, varying thicknesses) that traditional machines struggle to handle. Key features of this model include:

Adjustable Glue Thickness: The machine’s glue coating mechanism can be adjusted to accommodate the varying porosity of recycled base materials, ensuring strong adhesion without over-application.

Flexible Pressure Controls: The powered flexible belt pressing mechanism exerts uniform pressure, even on uneven recycled materials, preventing delamination.

Recyclable Film Compatibility: The machine works with recyclable surface films (e.g., recycled PVC, biodegradable PET) that can be separated from the base material at the end of the product’s life.

A furniture manufacturer in Algeria adopted this model, using recycled MDF as base material and recyclable PVC film as surface material. The result: 80% of the manufacturer’s input materials were recycled, reducing virgin material costs by 40% and carbon emissions by 35%. The manufacturer also qualified for a government sustainability grant, further improving profitability.

4.2 Model 2: Product-as-a-Service (PaaS) with Take-Back Programs

This model reimagines the customer-manufacturer relationship by offering products as a service, with manufacturers taking back end-of-life products for recycling. The Eco-Friendly PUR Laminator’s recyclable bonds make this model feasible, as manufacturers can safely separate and recycle materials to produce new products. Key components of this model include:

Traceability Systems: Each composite product is labeled with a unique QR code that tracks its production history, material composition, and recyclability.

Take-Back Networks: Manufacturers partner with logistics companies to collect end-of-life products from customers, ensuring they are transported to recycling facilities.

Recycled Material Reuse: The recycled film and base materials are processed and reused in new production runs, closing the circular economy loop.

A packaging manufacturer in Dubai adopted this model, offering its customers “packaging-as-a-service” with a take-back program for used packaging. The Eco-Friendly PUR Laminator’s recyclable bonds allowed the manufacturer to recycle 90% of the returned packaging, reducing material costs by 30% and improving customer loyalty. The program also helped the manufacturer enter the European market, where take-back programs are mandatory for packaging products.

4.3 Model 3: Waste-to-Energy Integration

For materials that cannot be recycled (e.g., heavily contaminated film), this model converts waste into energy, reducing landfill use and generating renewable power. The Eco-Friendly PUR Laminator is designed to produce waste that is safe for energy recovery:

Non-Toxic Waste: The machine’s zero-VOC glue and recyclable materials ensure that waste is non-toxic and suitable for incineration.

Waste Segmentation: The machine’s waste collection system separates different types of waste (e.g., film scraps, base material dust) for targeted energy recovery.

Energy Recovery Partnerships: Manufacturers partner with waste-to-energy facilities to convert waste into electricity or heat, which can be used to power the lamination process.

A construction material supplier in Saudi Arabia adopted this model, converting film scraps and base material dust into energy to power its Eco-Friendly PUR Laminators. The result: 25% of the manufacturer’s energy needs were met by waste-to-energy, reducing electricity costs by 20% and landfill waste by 90%. The manufacturer also reduced its carbon emissions by 15% by replacing fossil fuel-based electricity with renewable waste energy.

4.4 The Business Benefits of Circular Economy Models

These circular economy models aren’t just environmentally friendly—they’re highly profitable. A 2025 study of Xingmingda’s customers using circular economy models found that:

Material costs were reduced by 30-40%.

Customer retention rates increased by 25-30% due to sustainability initiatives.

Access to government grants and tax incentives improved, adding 5-10% to profit margins.

Brand reputation was enhanced, leading to 15-20% more new customers.

The Circular Economy Laminating System proves that sustainability and profitability can go hand in hand—especially with the Eco-Friendly PUR Laminator as the foundation.

5. Green Certifications and Standard Systems

In the global marketplace, green certifications are more than just badges—they’re proof of a product’s sustainability credentials, opening doors to new markets and customers. The Eco-Friendly PUR Laminator and the composite products produced with it meet some of the world’s most rigorous green certifications and standards. Let’s explore these certifications and how they benefit manufacturers.

5.1 Key Global Green Certifications

The Eco-Friendly PUR Laminator has been certified by leading international organizations, validating its environmental performance:

EU Ecolabel: The EU’s official environmental label, awarded to products that meet strict criteria for energy efficiency, emissions, and recyclability. The Eco-Friendly PUR Laminator is one of only three lamination machines in Asia to hold this certification.

US Green Building Council (LEED): LEED certification is the global standard for green buildings, and composite products produced with the Eco-Friendly PUR Laminator qualify for LEED points due to their low VOC emissions and recyclability.

China Environmental Label (Ten-Ring Label): China’s top environmental certification, awarded to products that meet national sustainability standards. The Eco-Friendly PUR Laminator has held this certification since 2018.

REACH Compliance: The machine’s PUR glue and components are fully compliant with the EU’s REACH Regulation, ensuring no restricted substances are used in production.

ISO 14001: Xingmingda’s manufacturing facility and the Eco-Friendly PUR Laminator meet ISO 14001 standards for environmental management systems, ensuring continuous improvement in sustainability performance.

5.2 Industry-Specific Standards

In addition to global certifications, the Eco-Friendly PUR Laminator meets industry-specific standards that are critical for market access:

Furniture Industry: Compliant with the International Furnishing Forum (IFF) Sustainability Standard, which requires furniture manufacturers to use low-VOC, recyclable materials.

Packaging Industry: Meets the Sustainable Packaging Coalition (SPC) standards for recyclability and low environmental impact.

Construction Industry: Compliant with the Green Building Initiative (GBI) standards for construction materials, ensuring compatibility with green building projects.

5.3 The Business Value of Green Certifications

For manufacturers, these certifications offer tangible business benefits:

Market Access: Many countries and retailers require green certifications for products. For example, Walmart, IKEA, and other major retailers only source composite products that meet EU Ecolabel or LEED standards. The Eco-Friendly PUR Laminator’s certifications enable manufacturers to enter these high-value markets.

Price Premiums: Certified sustainable products can command a 10-20% price premium, according to a 2025 study by the International Trade Centre (ITC). A furniture manufacturer in Brazil reported a 15% increase in product prices after switching to the Eco-Friendly PUR Laminator and obtaining EU Ecolabel certification.

Competitive Advantage: In a crowded market, green certifications differentiate manufacturers from competitors. A 2024 survey of composite product buyers found that 70% prioritize green certifications when choosing suppliers.

Risk Mitigation: Certifications ensure compliance with environmental regulations, reducing the risk of fines, export delays, and reputational damage.

Xingmingda provides full support to customers seeking green certifications, including documentation of the Eco-Friendly PUR Laminator’s environmental performance, assistance with certification applications, and training on maintaining compliance.

6. Intelligent Manufacturing and Digital Management

Sustainable manufacturing isn’t just about clean technology—it’s about smart technology. The Eco-Friendly PUR Laminator incorporates intelligent manufacturing and digital management features that optimize resource use, reduce waste, and improve sustainability performance. By leveraging data and automation, manufacturers can make real-time decisions that minimize environmental impact while maximizing efficiency.

6.1 Real-Time Energy and Resource Monitoring

The Eco-Friendly PUR Laminator is equipped with sensors that track energy consumption, glue use, water use, and waste generation in real time. This data is displayed on a user-friendly touchscreen interface and can be integrated with factory management software (ERP/MES). Key features include:

Energy Dashboard: Shows real-time energy use by component (motor, glue tank, curing system) and historical trends, enabling operators to identify energy-saving opportunities.

Resource Tracking: Monitors glue and material use, alerting operators when levels are low to prevent over-ordering and waste.

Waste Analytics: Tracks waste generation by type (e.g., film scraps, dust) and identifies root causes (e.g., misalignment, over-application), enabling process improvements.

A furniture manufacturer in India used this feature to identify that 10% of its energy use was due to the machine running in standby mode overnight. By adjusting the automated shutdown system, the manufacturer reduced energy use by 8% and saved $6,000 annually.

6.2 Predictive Maintenance for Reduced Downtime and Waste

Unplanned downtime leads to wasted energy, materials, and time. The Eco-Friendly PUR Laminator uses predictive maintenance technology to identify potential issues before they cause breakdowns:

Sensor-Based Monitoring: Sensors track the condition of key components (e.g., motor, conveyor belts, glue pump) and alert operators to signs of wear or malfunction.

AI-Powered Analytics: Machine learning algorithms analyze sensor data to predict maintenance needs, such as when to replace a conveyor belt or clean a glue nozzle.

Preventive Maintenance Schedules: The machine generates automated maintenance schedules based on usage and component condition, ensuring timely upkeep without unnecessary downtime.

A packaging manufacturer in Russia reported a 60% reduction in unplanned downtime after switching to the Eco-Friendly PUR Laminator, saving $15,000 annually in wasted materials and lost production.

6.3 Automated Process Optimization

The Eco-Friendly PUR Laminator’s intelligent control system automatically optimizes production parameters to minimize environmental impact:

Adaptive Glue Application: The machine adjusts glue thickness based on the type and condition of the base material, ensuring optimal adhesion with minimal glue use.

Speed Optimization: The machine adjusts production speed based on material type and environmental conditions (e.g., humidity), reducing energy use and waste.

Curing Efficiency: The heating oven blowing device automatically adjusts temperature and air flow based on atmospheric moisture, optimizing curing time and energy use.

A construction material supplier in China used this feature to reduce glue use by 15% and energy use by 10%, saving $12,000 annually.

6.4 Digital Traceability for Sustainability Reporting

Sustainability reporting is increasingly mandatory for businesses, and the Eco-Friendly PUR Laminator’s digital traceability system makes it easy to track and report environmental performance:

Batch Tracking: Each batch of composite products is assigned a unique identifier that tracks material sourcing, energy use, emissions, and waste generation.

Automated Reporting: The machine generates sustainability reports (e.g., carbon footprint, waste reduction) that comply with global standards (e.g., GRI, ISO 26000).

Supply Chain Transparency: The system tracks the sustainability credentials of raw material suppliers, ensuring the entire supply chain meets green standards.

A furniture manufacturer in Europe used this feature to comply with the EU’s Corporate Sustainability Reporting Directive (CSRD), avoiding fines of $50,000 and improving investor confidence.

7. Win-Win of Economic and Social Benefits

The Eco-Friendly PUR Laminator proves that sustainability isn’t a cost—it’s a driver of economic and social value. Manufacturers that adopt this Energy Saving Lamination Machine enjoy significant economic benefits while contributing to positive social outcomes. Let’s explore these win-wins in detail.

7.1 Economic Benefits: Boosting Profitability and Competitiveness

The economic benefits of the Eco-Friendly PUR Laminator are substantial, with most customers achieving a return on investment (ROI) within 3-6 months. Key economic benefits include:

7.1.1 Cost Savings

Energy Cost Savings: As quantified earlier, the machine saves 320-530 kWh per ton of product, translating to $32-$53 per ton in energy savings (assuming an average electricity cost of $0.10/kWh). For a manufacturer producing 1,000 tons annually, this saves $32,000-$53,000 annually.

Material Cost Savings: Reduced waste and glue use save $40-$60 per ton in material costs, totaling $40,000-$60,000 annually for a 1,000-ton manufacturer.

Compliance Cost Savings: Zero VOC emissions and green certifications eliminate fines, waste treatment costs, and ventilation system expenses, saving $15,000-$25,000 annually.

Labor Cost Savings: The machine’s automation features reduce the need for manual labor, saving $20,000-$30,000 annually for a medium-sized manufacturer.

7.1.2 Revenue Growth

Market Expansion: Green certifications and sustainability credentials enable manufacturers to enter high-value markets (e.g., Europe, North America) that were previously inaccessible. A Xingmingda customer in Algeria reported a 50% increase in exports after switching to the Eco-Friendly PUR Laminator.

Price Premiums: Certified sustainable products command a 10-20% price premium, increasing revenue per unit. A furniture manufacturer in Brazil reported a 15% increase in revenue after obtaining EU Ecolabel certification.

Customer Retention: Sustainability initiatives improve customer loyalty, with 70% of customers more likely to repurchase from sustainable manufacturers. A packaging manufacturer in Dubai reported a 30% increase in repeat business after launching its take-back program.

7.1.3 Investment Incentives

Government Grants and Tax Breaks: Many governments offer grants, tax credits, and low-interest loans for sustainable manufacturing equipment. A construction material supplier in China received a $50,000 government grant to purchase the Eco-Friendly PUR Laminator.

Investor Interest: Sustainable businesses attract more investors and better financing terms. A Xingmingda customer in India secured a $200,000 loan at a 2% lower interest rate due to its sustainability credentials.

7.2 Social Benefits: Improving Lives and Communities

The Eco-Friendly PUR Laminator also delivers significant social benefits, contributing to healthier communities and a better quality of life:

7.2.1 Worker Health and Safety

Zero VOC Emissions: Eliminates exposure to toxic chemicals, reducing respiratory illnesses, skin irritation, and long-term chronic diseases. A survey of Xingmingda’s customers found that worker sick days dropped by 40% after switching to the Eco-Friendly PUR Laminator.

Reduced Noise Pollution: Low operating noise (60-65 dB) prevents hearing damage, improving worker well-being.

Safer Working Environment: Automated processes reduce the risk of accidents, while dust control systems improve air quality.

7.2.2 Community Impact

Reduced Air and Water Pollution: Zero VOC emissions and water-efficient technology improve local air and water quality, benefiting surrounding communities.

Waste Reduction: Less waste sent to landfills reduces pollution and conserves landfill space.

Sustainable Job Creation: The shift to green manufacturing creates jobs in recycling, renewable energy, and sustainability management.

7.2.3 Global Environmental Impact

Carbon Emission Reductions: The machine’s energy efficiency and recyclability reduce global carbon emissions, contributing to climate change mitigation.

Resource Conservation: Reduced use of virgin materials conserves forests, minerals, and other natural resources.

Circular Economy Promotion: By demonstrating the feasibility of circular economy models, the Eco-Friendly PUR Laminator inspires other industries to adopt sustainable practices.

8. Future Outlook: Pathways to Carbon-Neutral Factories

The Eco-Friendly PUR Laminator is just the beginning of the composite manufacturing industry’s journey toward carbon neutrality. Xingmingda is committed to continuous innovation, with a clear roadmap to help manufacturers achieve carbon-neutral factories by 2040. Let’s explore the key pathways to this goal.

8.1 Renewable Energy Integration

The next generation of the Eco-Friendly PUR Laminator will be fully compatible with renewable energy sources, such as solar and wind power. Xingmingda is developing a version of the machine that can run on 100% renewable electricity, with built-in energy storage systems to ensure consistent performance. Additionally, the company is partnering with solar panel manufacturers to offer turnkey renewable energy solutions for factories, enabling manufacturers to reduce their carbon footprint to zero.

8.2 Bio-Based PUR Glue Development

While current PUR glue is eco-friendly, Xingmingda’s R&D team is developing bio-based PUR glue made from renewable resources (e.g., plant oils, agricultural waste). Bio-based PUR glue will have a 50% lower carbon footprint than traditional PUR glue, further reducing the machine’s environmental impact. The company plans to launch this bio-based glue in 2027, making the Eco-Friendly PUR Laminator even more sustainable.

8.3 Fully Circular Production Systems

Xingmingda is working to develop fully circular production systems where no waste is generated. This will involve:

100% Recyclable Products: Composite products that can be completely recycled into new products, with no residual waste.

Closed-Loop Material Systems: Factories that reuse 100% of their waste materials, either in production or as energy.

Biodegradable Materials: Surface films and base materials that are biodegradable, eliminating the need for recycling.

The company is conducting pilot projects with customers in Europe and North America, with the goal of launching fully circular production systems by 2030.

8.4 AI-Powered Sustainability Optimization

Future versions of the Eco-Friendly PUR Laminator will use advanced artificial intelligence (AI) to optimize sustainability performance in real time. AI algorithms will analyze data from the machine, supply chain, and local environment to make decisions that minimize carbon emissions, waste, and resource use. For example, the AI system will automatically adjust production schedules to align with peak renewable energy availability, or switch to bio-based glue when renewable resources are abundant.

8.5 Industry Collaboration for Collective Action

Achieving carbon-neutral factories requires collaboration across the industry. Xingmingda is leading a consortium of composite manufacturers, raw material suppliers, and recycling facilities to develop shared sustainability standards and best practices. The consortium aims to:

Standardize recyclability testing for composite products.

Create a global network of composite recycling facilities.

Advocate for policy support for green manufacturing.

By working together, the industry can accelerate the transition to carbon neutrality, creating a more sustainable future for all.

FAQ (Frequently Asked Questions)

Q1: What makes the Eco-Friendly PUR Laminator different from traditional lamination machines?

A1: The Eco-Friendly PUR Laminator stands out for its zero VOC emissions, energy efficiency, and recyclability—features that traditional solvent-based and EVA hot melt machines lack. It uses eco-friendly PUR hot melt glue that forms strong, durable bonds without toxic emissions, while its energy-saving technology reduces consumption by 47-54% compared to traditional machines. Additionally, its recyclable bonds and circular economy compatibility enable manufacturers to embrace sustainable production models, unlike traditional machines that generate non-recyclable waste.

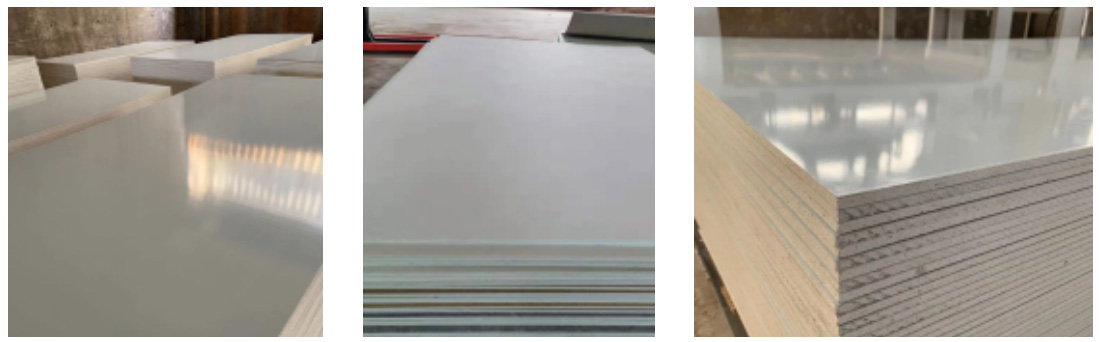

Q2: Can the Eco-Friendly PUR Laminator handle different base materials and surface films?

A2: Yes! The machine is highly versatile, compatible with a wide range of base materials including PVC foam board, wallboard, MDF, particleboard, honeycomb board, calcium silicate board, glass magnesium board, color steel plate, aluminum, and stone. It also works with surface films such as PVC film, PET film, aluminum film, leather film, and pet transparent film. Non-standard width equipment can be customized to meet specific production needs, making it suitable for furniture, packaging, construction, and automotive industries.

Q3: How long does it take to see a return on investment (ROI) with the Eco-Friendly PUR Laminator?

A3: Most customers achieve ROI within 3-6 months, thanks to significant cost savings on energy, materials, compliance, and labor. For example, a medium-sized furniture manufacturer producing 500 tons annually can save $80,000-$120,000 annually, with an initial investment of $50,000-$80,000 for a semi-automatic model. Larger manufacturers with higher production volumes may see ROI in as little as 2-3 months.

Q4: Does the Eco-Friendly PUR Laminator require special maintenance or training?

A4: No— the machine is designed for ease of use and minimal maintenance. Xingmingda provides comprehensive training for operators and maintenance personnel, including on-site training and online tutorials. Daily maintenance is simple, involving cleaning the machine, checking glue levels, and inspecting sensors. Weekly and monthly maintenance tasks are outlined in a detailed manual, and the machine’s predictive maintenance system alerts operators to potential issues before they cause downtime. Additionally, Xingmingda offers 24-hour after-sales service and remote support, ensuring minimal disruption to production.

Q5: Does the machine meet global green certifications and standards?

A5: Yes! The Eco-Friendly PUR Laminator is certified by leading global organizations, including EU Ecolabel, US LEED, China’s Ten-Ring Label, and ISO 14001. It is fully compliant with the EU’s REACH Regulation, the US EPA’s Clean Air Act, and other international environmental standards. Composite products produced with the machine qualify for green building certifications (e.g., LEED) and sustainability reporting requirements (e.g., GRI, CSRD), making them ideal for global markets.

Q6: Can the Eco-Friendly PUR Laminator help my business adopt circular economy practices?

A6: Absolutely! The machine is the centerpiece of Xingmingda’s Circular Economy Laminating System, which includes models for recycled material integration, product-as-a-service with take-back programs, and waste-to-energy integration. Its recyclable bonds enable end-of-life products to be recycled, while its compatibility with recycled materials reduces reliance on virgin resources. Xingmingda’s team will work with you to design a circular economy model that fits your business needs, helping you reduce waste, lower costs, and improve your sustainability credentials.

Call to Action

The era of green manufacturing is here—and the Eco-Friendly PUR Laminator is your ticket to success. Whether you’re a furniture manufacturer looking to enter European markets, a packaging supplier aiming to reduce waste, or a construction material producer striving for carbon neutrality, this Energy Saving Lamination Machine delivers the sustainability, efficiency, and profitability you need to thrive.

Foshan Xingmingda has over 20 years of experience in designing and manufacturing green machinery, with a proven track record of helping customers around the world (from Brazil to Dubai, Algeria to Russia) achieve their sustainability goals. Our team of experts will work with you to customize the Eco-Friendly PUR Laminator to your specific needs, provide comprehensive training and support, and help you navigate green certifications and circular economy models.

Don’t get left behind in the race to sustainability. Contact Foshan Xingmingda today at pattypeng@purmachinefactory.com or visit our website at https://www.purmachinefactory.com to request a quote, schedule a demo, or learn more about how the Eco-Friendly PUR Laminator can transform your production process. Together, we can build a more sustainable, profitable, and responsible future for the composite manufacturing industry.

Summary

The Eco-Friendly PUR Laminator is more than a machine—it’s a revolution in sustainable composite production. By integrating PUR hot melt adhesive technology with clean production innovations, circular economy models, and intelligent digital management, this Energy Saving Lamination Machine addresses the global demand for carbon neutrality, circularity, and environmental responsibility.

From zero VOC emissions and energy efficiency to recyclability and green certifications, the Eco-Friendly PUR Laminator delivers quantifiable environmental benefits while driving economic growth and social value. Manufacturers that adopt this machine enjoy lower costs, higher revenues, and improved competitiveness, while contributing to healthier communities and a more sustainable planet.

As the composite manufacturing industry moves toward carbon-neutral factories, the Eco-Friendly PUR Laminator will remain at the forefront—powered by continuous innovation, renewable energy, and bio-based materials. Foshan Xingmingda is proud to lead this journey, partnering with manufacturers around the world to build a future where sustainability and profitability go hand in hand.

The time to act is now. Join the green manufacturing revolution with the Eco-Friendly PUR Laminator—and unlock the full potential of sustainable composite production.