In the past, lamination was often viewed as a purely manual finishing process—labor-intensive, experience-driven, and highly dependent on skilled operators. Today, however, the rapid evolution of automation technology has transformed lamination into one of the most critical productivity engines in the packaging and printing industry. At the center of this transformation stands the Automatic Lamination Machine, reshaping efficiency, precision, consistency, and sustainability across global production lines.

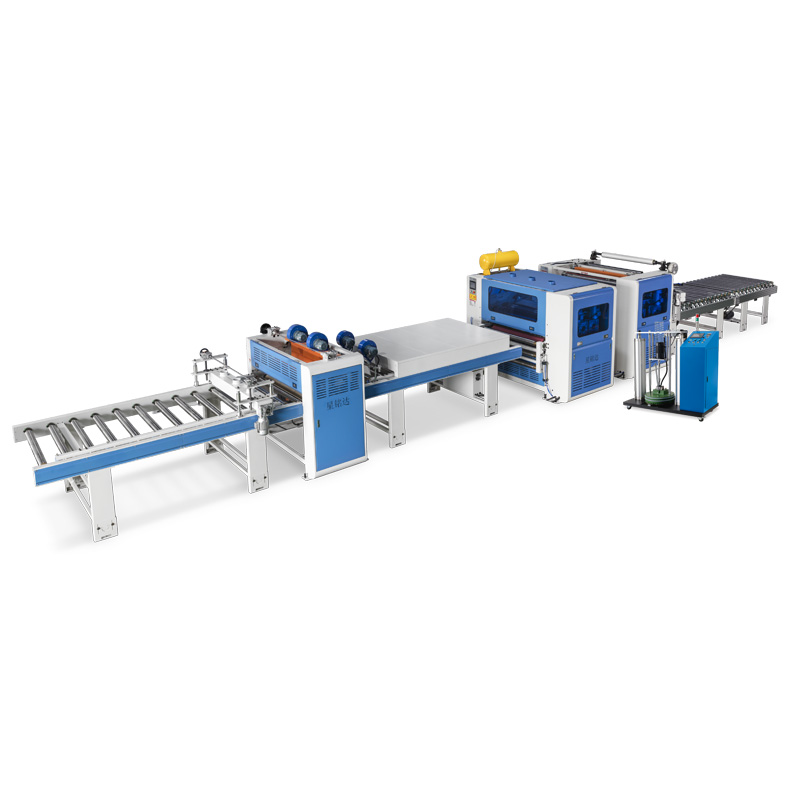

Founded in 2004, Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd., located in Lunjiao Town, Shunde—China’s renowned woodworking machinery hub—has been deeply involved in the design and manufacture of advanced lamination and wrapping solutions. With a strong focus on technology, quality, and customer satisfaction, Xingmingda continues to push the boundaries of intelligent lamination through its Fully Automatic Film Laminator, High Speed Laminating Equipment, Digital Laminating Machine, and Commercial Laminating Machine solutions.

1. The Limitations of Traditional Manual Lamination

Despite decades of use, traditional lamination methods face fundamental limitations that restrict scalability and quality stability.

Efficiency Bottlenecks

A skilled operator can manually laminate approximately 300–500 A3 sheets per hour, depending on material and film type. This output is insufficient for modern, high-volume production environments where delivery speed directly impacts competitiveness. In contrast, a modern Automatic Lamination Machine can process thousands of sheets per hour with stable performance.

Accuracy and Waste

Manual positioning errors typically range between ±2–3 mm, leading to frequent misalignment and trimming issues. As a result, scrap rates can reach 8–12%, significantly increasing production costs. Automated systems such as a Fully Automatic Film Laminator reduce positioning deviation to less than ±0.5 mm, ensuring higher yield and repeatable results.

Labor Intensity and Working Conditions

Manual lamination exposes workers to heat, noise, and adhesive odors for extended periods. Fatigue directly affects quality consistency. A Commercial Laminating Machine minimizes human intervention, improving workplace safety while stabilizing output quality.

Material Loss

During setup and adjustment, traditional processes waste 15–20% of film and adhesive materials. Intelligent parameter control in High Speed Laminating Equipment drastically reduces setup loss and ensures optimal adhesive distribution from the first sheet onward.

2. Automation as the New Industry Standard

The transition from manual lamination to intelligent automation is not merely an equipment upgrade—it is a strategic shift.

A modern Automatic Lamination Machine integrates precision feeding, tension control, temperature regulation, and pressure optimization into one synchronized system. When combined with digital controls, a Digital Laminating Machine allows operators to store, recall, and fine-tune process parameters for different jobs within minutes.

For large-scale operations, High Speed Laminating Equipment delivers continuous output while maintaining consistent bonding quality. Meanwhile, a Fully Automatic Film Laminator enables unattended operation, reducing labor dependency and operational variability.

3. Expanding Application Scenarios

Automation has significantly broadened the application scope of lamination technology.

Book and Magazine Printing

Cover lamination for books and magazines requires flawless surface finish and durability. An advanced Commercial Laminating Machine can handle up to 30,000 books per day, maintaining uniform gloss and adhesion.

Packaging Box Manufacturing

From cardboard to corrugated paper, packaging lamination demands adaptability. An Automatic Lamination Machine effortlessly processes various substrates and box structures, ensuring visual appeal and structural protection.

Advertising and Display Production

Posters, display boards, and promotional materials often require large-format lamination. High Speed Laminating Equipment supports widths of up to 1.6 meters, meeting the demands of commercial advertising.

Specialty Printing

Security labels, certificates, and anti-counterfeit materials rely on precision lamination. A Digital Laminating Machine ensures accurate control for sensitive applications.

Electronics and Industrial Printing

User manuals, labels, and technical documents benefit from durable lamination provided by a Fully Automatic Film Laminator, ensuring resistance to wear and environmental exposure.

4. Environmental and Energy Efficiency Upgrades

Sustainability is no longer optional—it is a core purchasing criterion.

Modern Automatic Lamination Machine designs incorporate solvent recovery systems that reduce VOC emissions by up to 95%. Energy-efficient drives allow standby power consumption to remain below 500W, while intelligent energy-saving modes activate automatically during idle periods.

Adhesive utilization efficiency has improved to 98%, significantly reducing waste. Noise control technology keeps operational sound levels below 70 dB, creating a more comfortable production environment. These advancements position the Commercial Laminating Machine as both an economic and environmentally responsible investment.

5. Industry Performance Comparison Table

| Parameter | Manual Lamination | Automatic Lamination Machine |

| Output Capacity | 300–500 sheets/hour | 3,000–8,000 sheets/hour |

| Positioning Accuracy | ±2–3 mm | ≤±0.5 mm |

| Scrap Rate | 8–12% | <2% |

| Adhesive Utilization | 80–85% | Up to 98% |

| VOC Emissions | High | Reduced by 95% |

| Noise Level | >80 dB | <70 dB |

| Labor Dependency | High | Low |

6. Frequently Asked Questions (FAQ)

Q1: Is an Automatic Lamination Machine suitable for small and medium-sized print shops?

Yes. With modular configurations and scalable options, a Digital Laminating Machine can be adapted to both small workshops and large factories.

Q2: How fast is the return on investment?

Most customers recover their investment within 12–24 months through labor savings, reduced waste, and increased throughput.

Q3: Can one machine handle multiple materials?

Absolutely. A Fully Automatic Film Laminator is designed to process paper, cardboard, and specialty substrates with minimal adjustment.

Q4: Is operator training complicated?

No. Modern Commercial Laminating Machine systems feature intuitive interfaces, reducing training time significantly.

7. A Strategic Call to Action

In a competitive market where efficiency, quality, and sustainability define success, upgrading to intelligent lamination is no longer a luxury—it is a necessity. Choosing the right Automatic Lamination Machine, High Speed Laminating Equipment, or Digital Laminating Machine can fundamentally reshape your production capabilities.

At Xingmingda, we believe that technology and quality are the foundation of long-term competitiveness. Our Fully Automatic Film Laminator and Commercial Laminating Machine solutions are engineered to help global customers move from manual limitations to intelligent, future-ready production.

Conclusion

From manual craftsmanship to intelligent automation, lamination technology has evolved into a decisive force within the packaging and printing industry. By embracing advanced automation, manufacturers gain not only speed and consistency but also sustainability and strategic resilience.

With nearly two decades of experience,Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd. remains committed to delivering reliable, high-performance lamination solutions that power the next generation of packaging and printing excellence.

🌐 Website: https://www.purmachinefactory.com

📧 Email: pattypeng@purmachinefactory.com