For woodworking enterprises engaged in bulk production, low efficiency—marked by slow processing speeds, frequent downtime, and disjointed production links—has long been a bottleneck restricting profit growth. As a professional edge banding machines manufacturer, Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd. has launched a series of cutting-edge edge banding machines, targeting these pain points with innovative technology. These cutting-edge edge banding machines wholesale solutions not only boost single-machine efficiency but also realize seamless connection with the entire production line, helping enterprises break through efficiency bottlenecks in bulk production.

The core advantage of Xingmingda’s cutting-edge edge banding machines lies in their high-speed and stable processing capabilities. Equipped with a 3000W high-power servo motor and an optimized transmission system, the machines can achieve a maximum edge banding speed of 30 meters per minute—double the speed of traditional mid-range edge banding machines. Even during long hours of bulk production, the intelligent heat dissipation system maintains stable machine performance, reducing downtime caused by overheating by over 80%. A furniture manufacturer specializing in bulk cabinet production reported that after adopting Xingmingda’s machines, the daily output of edge-banded boards increased from 500 to 900, significantly cutting production cycles.

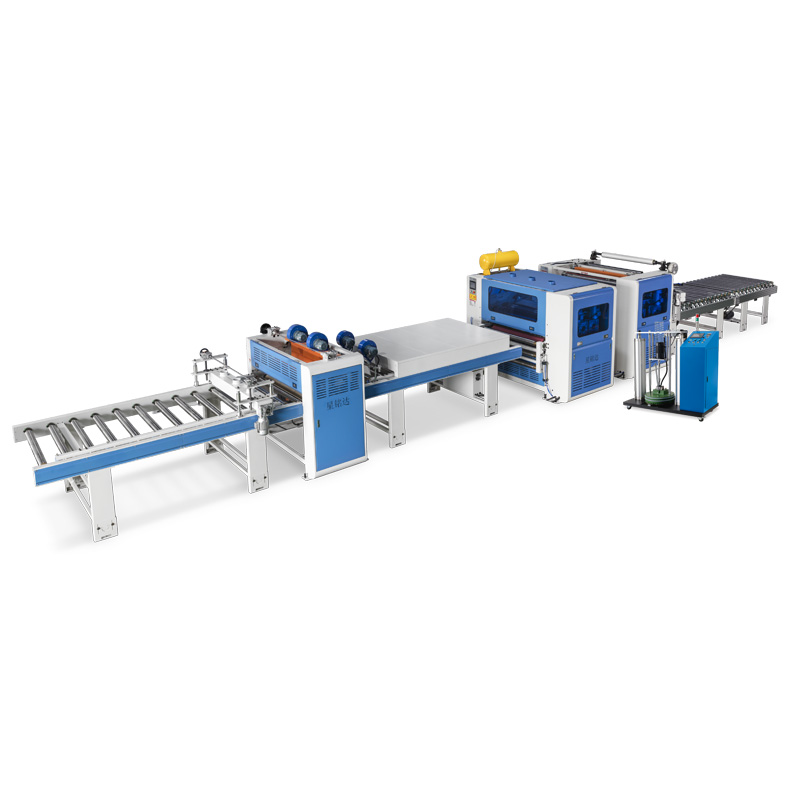

To further eliminate efficiency gaps in the production line, Xingmingda’s edge banding machines support seamless integration with other equipment under its brand. For example, when matched with wrapping machines factory productsand flat lamination machine supplier solutions, the machines form a fully automated production chain from board cutting, edge banding to surface lamination. The built-in industrial Internet of Things (IoT) module enables real-time data synchronization between devices, avoiding waiting time caused by information asynchronization. In addition, the integration of China automatic feeder for wrapping machine components into the edge banding line ensures a continuous and stable supply of edge materials. The automatic feeder can accurately adjust the feeding speed according to the edge banding speed, preventing material shortages or material accumulation that would interrupt the production process.

Xingmingda also provides customized efficiency-enhancing solutions based on the scale of enterprise production. For small and medium-sized enterprises with limited workshop space, the company has launched a compact cutting-edge edge banding machine that integrates edge banding, trimming, and polishing functions, saving 40% of the occupied area while ensuring efficiency. For large-scale enterprises with multi-variety and bulk production needs, the machines can be equipped with a flexible material sorting system, which automatically classifies edge-banded boards according to specifications, reducing manual sorting time by 60%.

“Achieving efficient and stable bulk production is the core demand of every woodworking enterprise,” said a technical director of Foshan Xingmingda. “Our cutting-edge edge banding machines not only pursue high speed but also focus on the overall efficiency of the production line. Through technology integration and customization, we help enterprises turn efficiency advantages into market competitiveness.” As the woodworking industry accelerates toward large-scale and intensive development, Xingmingda’s cutting-edge edge banding machines are becoming a key tool for enterprises to solve low efficiency in bulk production.