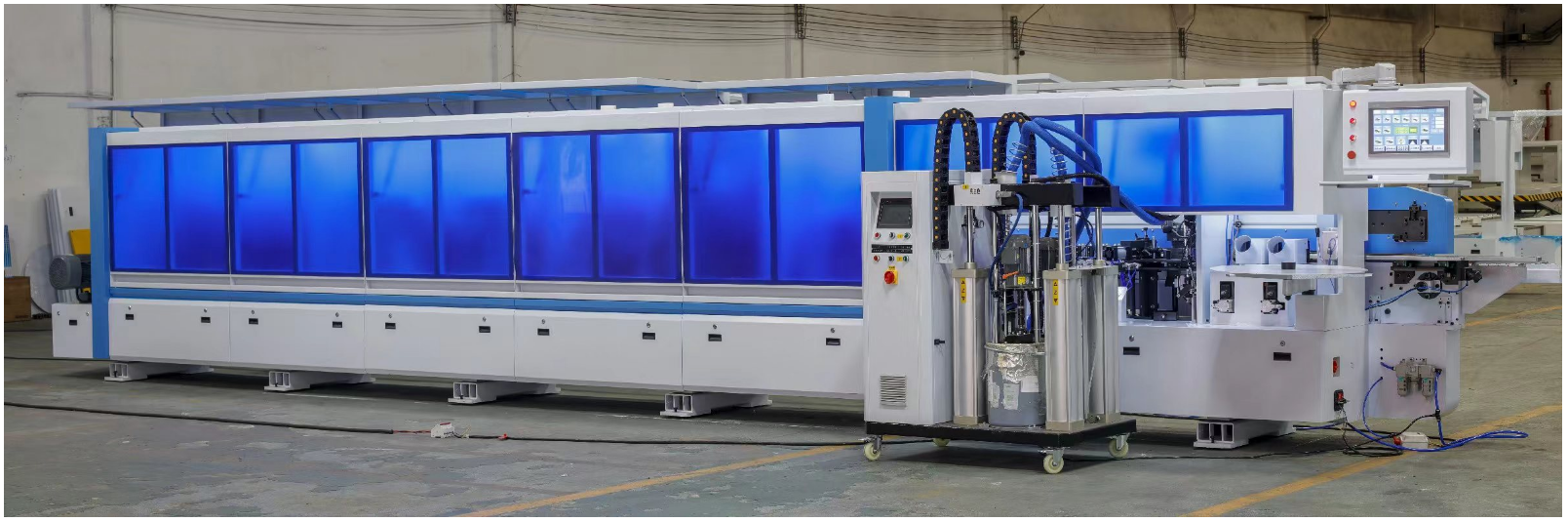

In the woodworking industry, inconsistent edge banding quality—such as uneven glue lines, loose bonding, or mismatched edge materials—has long been a major pain point for manufacturers. These issues not only damage the aesthetic appeal of finished furniture and wood products but also reduce their durability, leading to customer complaints and increased rework costs. As a leading edge banding machines manufacturer, Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd. has launched a new generation of edge banding machines equipped with precision technology, effectively solving these quality challenges while supporting compatibility with eco-friendly materials and integration with other woodworking equipment.

A core innovation of Xingmingda’s edge banding machines lies in their intelligent glue control system. Unlike traditional machines that often result in excessive or insufficient glue application, the new models feature high-precision glue nozzles and real-time pressure sensors. These components automatically adjust glue output based on the thickness of the edge material and the board, ensuring uniform glue spread across the entire edge. This not only eliminates visible glue lines—a key demand for high-end furniture production—but also enhances bonding strength, preventing edge peeling even under long-term use. For manufacturers using eco-friendly adhesives, the machines are also designed as water-based glue-compatible machines wholesale options, supporting low-VOC water-based glues without compromising performance, aligning with global environmental protection trends.

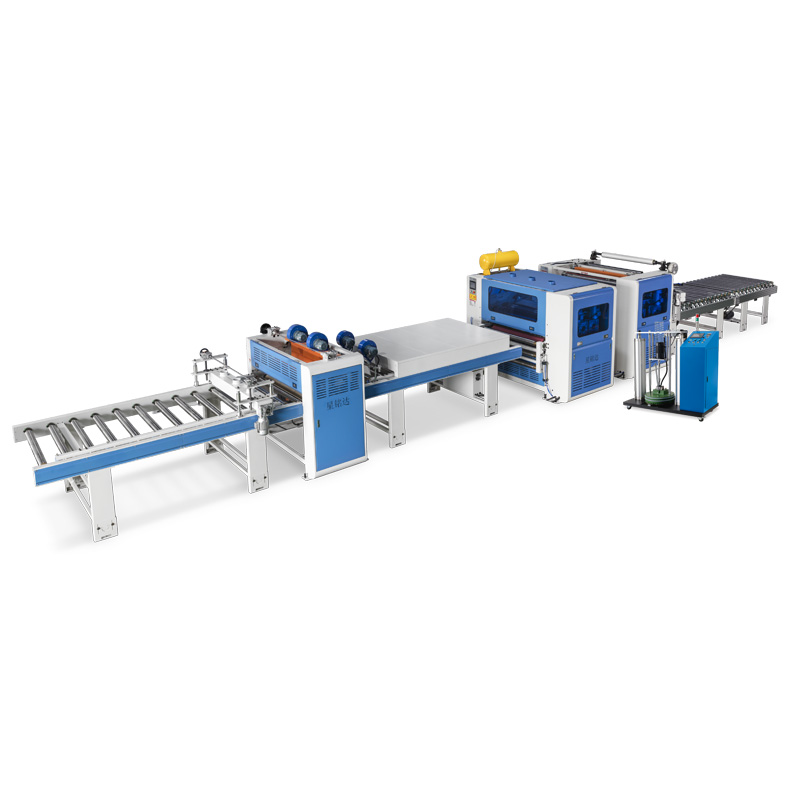

Another quality hurdle addressed by Xingmingda’s technology is material alignment accuracy. The edge banding machines are integrated with advanced optical positioning sensors that detect the edge of the board and the edge material in real time, correcting any deviations within 0.1mm. This ensures that the edge material fits perfectly with the board, avoiding mismatches or gaps that often occur with manual adjustment or less precise machines. Additionally, the machines support seamless integration with other equipment from Xingmingda, such as wrapping machines factory products and flat lamination machine supplier solutions. This allows manufacturers to build a fully automated production line, reducing manual intervention and further minimizing quality variations caused by human error.

To meet the diverse needs of small and large-scale manufacturers alike, Xingmingda also offers customized solutions, including the integration of China automatic feeder for wrapping machine components into edge banding lines. These automatic feeders ensure a steady and consistent supply of edge materials, preventing interruptions that can lead to uneven edge banding. “Our goal is to help woodworking enterprises turn quality hurdles into competitive advantages,” said a spokesperson for Foshan Xingmingda. “With precision technology and comprehensive equipment compatibility, our edge banding machines enable manufacturers to produce flawless products efficiently, reducing costs and boosting market competitiveness.”

As the woodworking industry continues to pursue higher quality standards and sustainability, Xingmingda’s edge banding machines are setting a new benchmark for precision and reliability, empowering manufacturers to overcome traditional quality challenges and thrive in a demanding market.