During the 138th Canton Fair, dozens of purchasing delegations from Europe, South America, the Middle East, and Southeast Asia visited Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd., engaging in lively exchanges and factory tours.

The factory’s intelligent and high-precision woodworking machinery drew strong interest from international buyers, demonstrating once again the global competitiveness of Made in China.

1. The Canton Fair: A Window Into China’s Smart Woodworking Industry

With the rapid growth of the global furniture and customized home industry, the woodworking machinery sector has entered a crucial era of intelligent and automated transformation.

Especially in the post-pandemic period, overseas demand for equipment such as the 1300 New Intelligent Laminating Machine, Keyhole Machine, Sliding Table Saw, and Cold Glue Laminating Production Line continues to surge.

As the world’s manufacturing powerhouse, China is promoting intelligent woodworking technology worldwide. The Canton Fair has become more than a product exhibition—it’s now a vital platform for technological exchange, international cooperation, and brand trust-building.

As a representative enterprise from Lunjiao, Shunde—China’s famous woodworking machinery town, Xingmingda once again showcased the true strength of Chinese smart manufacturing.

2. International Buyers Flocked to Xingmingda: Smart Equipment Stole the Spotlight

During the Canton Fair, Xingmingda’s factory in Foshan welcomed professional buyers from the United States, Canada, Italy, Poland, India, Saudi Arabia, and Vietnam.

They visited the production workshops, closely observing the precision, speed, and reliability of Xingmingda’s machinery lines.

Highlighted products included:

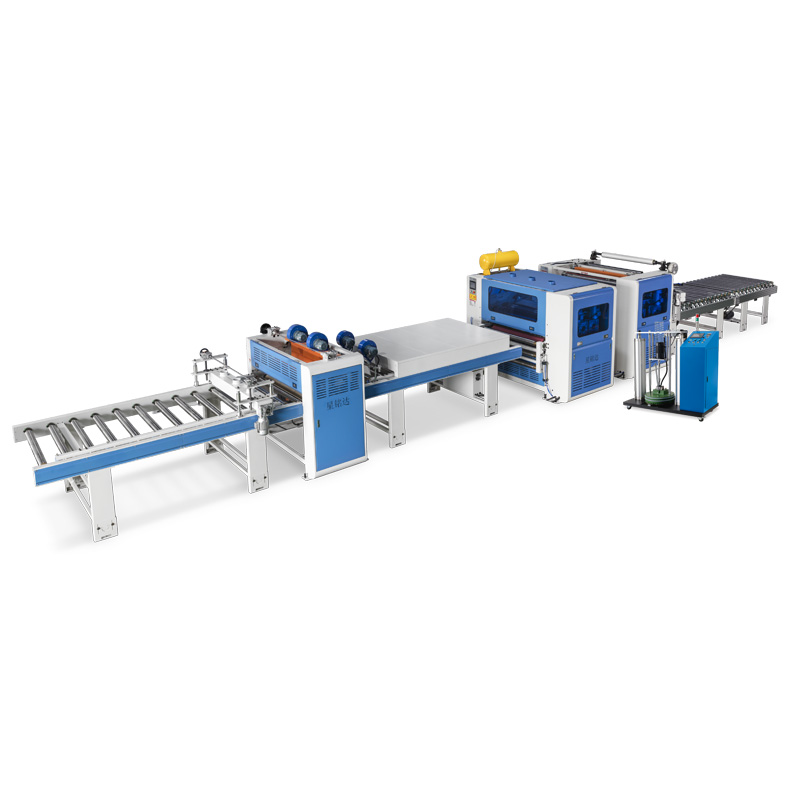

1300 New Intelligent Laminating Machine

Features intelligent temperature control and automatic tension adjustment. Adhesion stability improved by 30%, ensuring smooth, efficient operation.Keyhole Machine

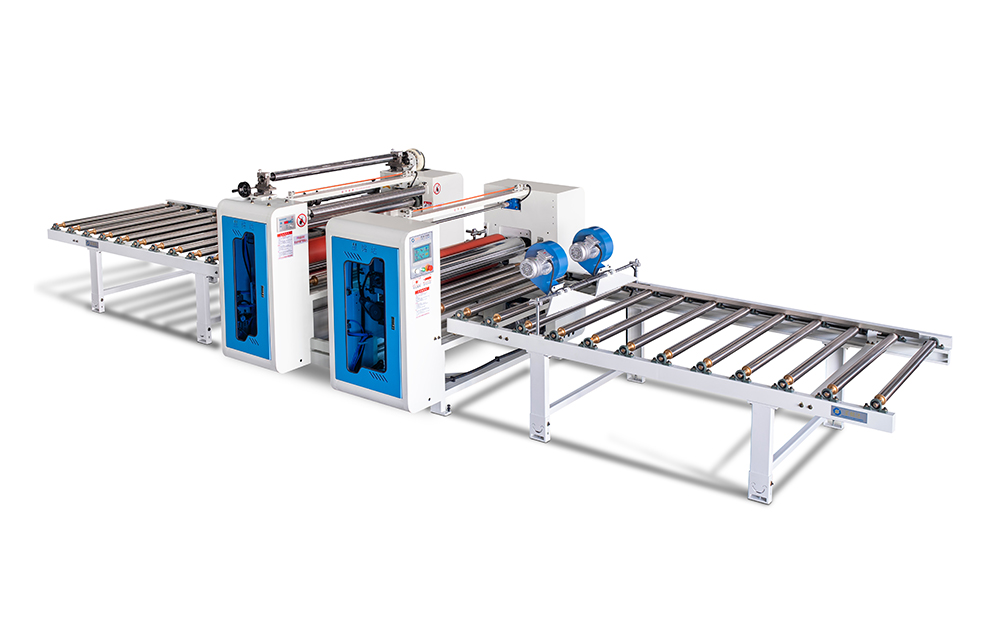

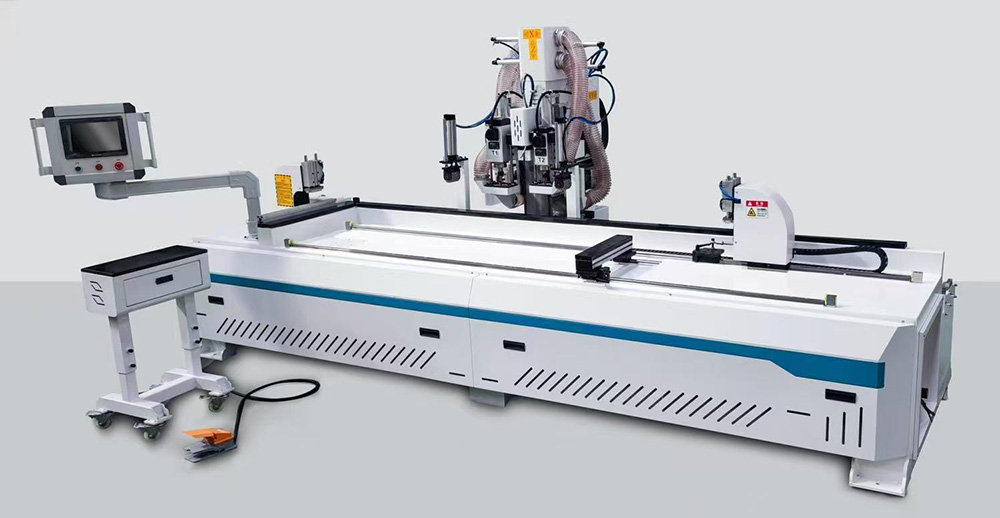

CNC-controlled for automatic positioning and cutting of door lock holes, achieving an accuracy of less than 0.1mm.Sliding Table Saw

Equipped with linear guide rails and electronic angle adjustment, offering stable, quiet cutting that meets European CE safety standards.Cold Glue Laminating Production Line

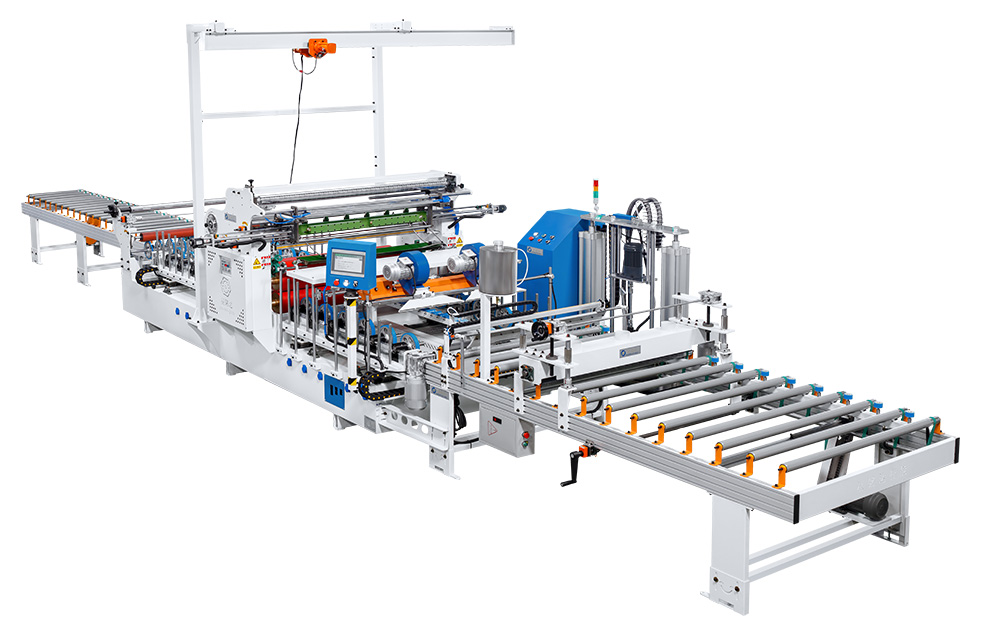

Eco-friendly and solvent-free, suitable for large-scale lamination of furniture panels, door panels, and decorative boards.2500 Wooden Door CNC Door Lock Machine

A multifunctional CNC center that integrates drilling, grooving, and milling—designed specifically for door manufacturers.

A Xingmingda spokesperson explained:

“Clients were impressed not just by the speed and precision of our machines, but by their reliability and energy efficiency. Through intelligent systems and automation, we help factories reduce labor costs and enhance product consistency—exactly what global manufacturers are looking for.”

| System | Professional CNC customized system |

| Name | 2500 Wooden door CNC door lock machine |

| Converter | Bethel 7.5KW |

| Servo motor | Dongling 750W servo motor x 3 |

| guide rail | Hongtai X-axis 25 Y-axis 25 Z-axis 20 |

| speed reducer | Xinbao reducer |

| Transmission method | High precision rack and pinion transmission |

| Doorlength | 0.3m-2.5m |

| Travel Y-axis | 190mm |

| Thickness of pressed material | 60mm |

| Dimension | 4170 with a dust-proof cloth bracket)x1920x1700mm |

| Weight | 1100KGS |

| packing oversize | 3750*1920*1700 mm |

| Model | MJ6132A |

| Maximum sawing length | 3200mm |

| Dimension of main saw blade | φ305xφ 30mm |

| Dimensions of saw blade | φ120xφ 20mm |

| Motor power of main saw | 5.5KW |

| Rotation speed of main saw | 4500-5500r/min |

| Motor power of slot saw | 0.75KW |

| Shaft speed of slot saw | 9000r/min |

| Degree of inclination | 0°-45° |

| weight | 1000kg |

3. Technology + Manufacturing: Xingmingda’s Intelligent “China Solution”

Founded in 2004, Xingmingda has specialized in the R&D and production of hot-melt coating machines, wrapping machines, slotting machines, PUR hot-melt laminating machines, and cold glue laminating machines.

The company operates advanced CNC machining centers, laser cutting systems, and automated assembly lines—ensuring end-to-end quality control from design to inspection.

Certified by ISO9001, Xingmingda also integrates ERP digital management to guarantee traceable production, consistent quality, and efficient service.

To better serve international clients, Xingmingda built a Remote Technical Assistance Platform, enabling real-time online calibration, software updates, and operator training worldwide—helping partners maintain top performance with minimal downtime.

4. Global Market Trends & Data Analysis

| Category | Representative Product | Market Growth (2024–2025) | Energy Saving | Labor Reduction | Application Field |

|---|---|---|---|---|---|

| Smart Lamination Equipment | 1300 New Intelligent Laminating Machine | 18% | 25% | 30% | Furniture panels, decorative surfaces |

| Precision Processing Equipment | Keyhole Machine / 2500 Wooden Door CNC Door Lock Machine | 22% | 20% | 40% | Door manufacturing, custom furniture |

| Cutting Equipment | Sliding Table Saw | 15% | 15% | 20% | Board cutting, cabinetry |

| Eco Lamination Systems | Cold Glue Laminating Production Line | 30% | 35% | 25% | Eco-friendly furniture, packaging |

According to market analysis, European and North American buyers emphasize energy efficiency and automation levels, while Middle Eastern and South Asian buyers prioritize cost-performance and easy maintenance.

Xingmingda’s machines strike a balance between high performance and high affordability, positioning the company competitively across multiple regions.

5. Customer Testimonials: Global Trust Earned Through Quality and Service

Lorenzo, an Italian furniture manufacturer, shared his experience:

“We were looking for a laminating machine that’s both stable and precise. Xingmingda’s 1300 New Intelligent Laminating Machine not only runs fast but automatically adjusts pressure according to material thickness—truly smart!”

Carlos, a client from Argentina, added:

“The 2500 Wooden Door CNC Door Lock Machine has saved us nearly 40% in labor time. The installation and training team was professional, and after-sales support was prompt.”

Such authentic client voices represent Xingmingda’s growing reputation as a trusted global manufacturing partner.

6. FAQ: Top Five Questions From Overseas Clients

Q1: Can Xingmingda machines be customized?

A: Yes. We provide full customization for your production scale, material type, and process requirements—including the 1300 New Intelligent Laminating Machine and Cold Glue Laminating Production Line.

Q2: How is after-sales service handled internationally?

A: Xingmingda offers remote video support, on-site installation, quick spare parts delivery, and a one-year warranty.

Q3: Does the Keyhole Machine support various door types?

A: Absolutely. The Keyhole Machine is compatible with multiple door thicknesses and materials, featuring automatic size recognition and quick production switching.

Q4: Are Sliding Table Saws CE certified?

A: Yes. All Sliding Table Saw models comply with European CE safety standards and use internationally branded electrical components.

Q5: Is the Cold Glue Laminating Production Line eco-friendly?

A: Yes. It adopts a low-energy, solvent-free lamination process with zero emissions—fully compliant with EU environmental regulations.

7. Corporate Culture: Quality Builds Reputation

Xingmingda firmly believes that quality drives trust and innovation sustains growth.

The company regularly holds internal training and cultural activities to strengthen professional skills and team cohesion.

By fostering a family-like workplace, Xingmingda ensures that every employee treats the factory’s success as their own mission.

“A strong reputation comes from durable, reliable, and credible quality.”

This belief has guided Xingmingda’s steady growth for over two decades.

8. Conclusion & Call to Action: Shaping the Future of Intelligent Manufacturing

As global manufacturing transitions toward digitalization and sustainability, the woodworking machinery industry is moving beyond price competition—toward a race of technological excellence and service value.

With advanced solutions represented by the 1300 New Intelligent Laminating Machine, Keyhole Machine, Sliding Table Saw, Cold Glue Laminating Production Line, and 2500 Wooden Door CNC Door Lock Machine, Xingmingda empowers factories worldwide with efficiency, precision, and energy savings.

Moving forward, Xingmingda will continue to lead the smart transformation of woodworking machinery and collaborate with global partners to build the next era of intelligent production.

📣 Join hands with Xingmingda — let the world witness the power of Chinese intelligent manufacturing!

— Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd.