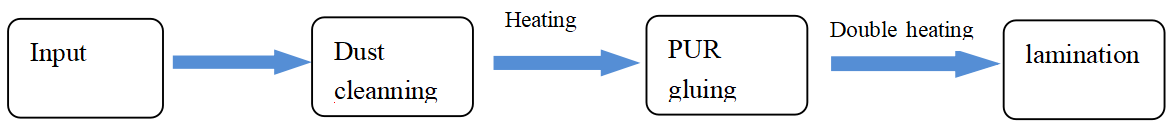

Cold Glue Lamination Machine

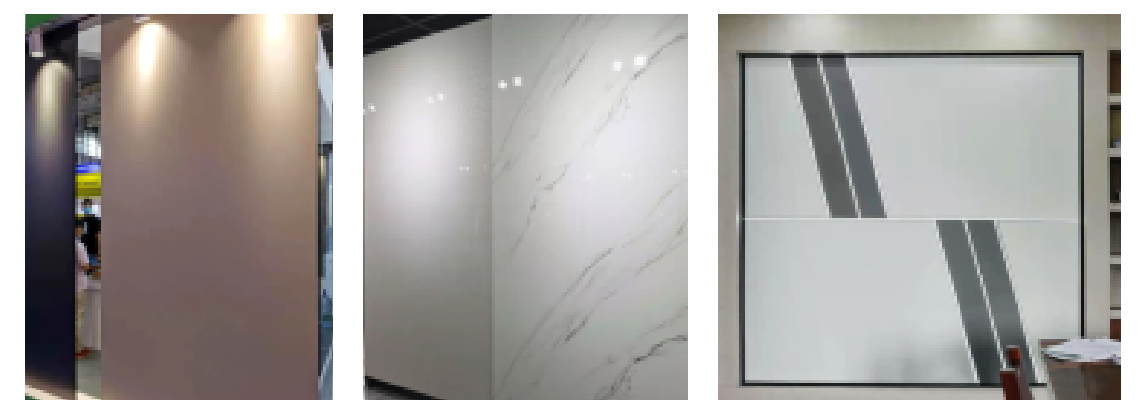

The device is designed to cover the surface sheet or wide plate profile by wrapping coated material.

The species can be MDF, particleboard, PVC board and aluminum metal sheet etc.using a special scraper or hot melt glue spraying system or PUR hot melt coating system to cover material, to get a perfect surface.

| Workpiece thickness | 3-40mm | Total power | 6.75kw |

| Max. Workpiece width | 1220mm | Machine dimensions | 9000x2445x3000mm |

| Working speed | 3-20m/min | Control method | PLC |

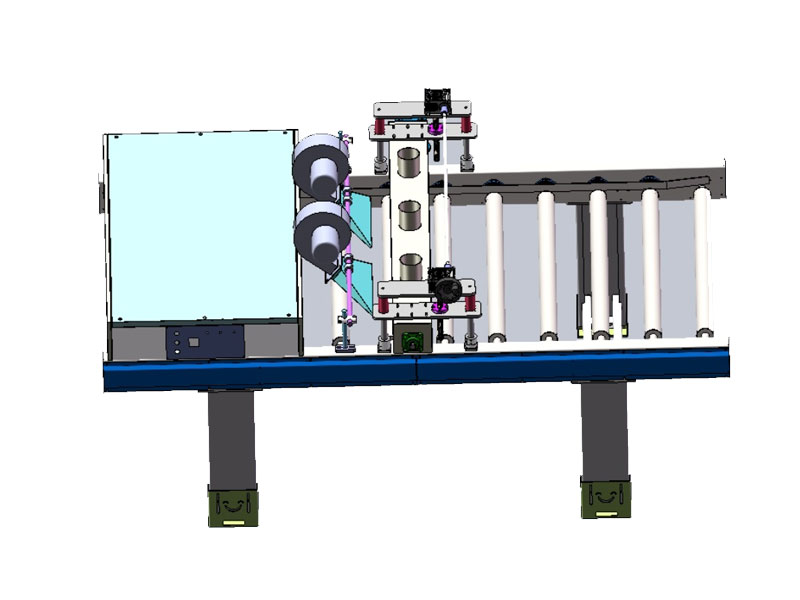

PUR Glue Tank:

Barrel :φ571mm Power type :AC380V/50HZ

Heighting power :15KW Melt speed:1~120kg/h

Temperature range:Normal atmospheric temperature --180℃

Working pressure :0.4~0.8MPa Pressure plate travel:Max:1100mm

Maximum speed of motor: 60rpm Maximum extraction pressure:50kg/cm2

Control system: PLC+ touch screen, Chinese interface, concise and intuitive

Safety protection system: Thermal insulation function:yes

Heating System:

Convey roller: dia ¢ 80*1400 stainess roller

power:0.75 KW ,length 3850MM

Heating box power:12 KW

Conveyor:

use ø80 chrome roller,

roller:80*1400 stainless power:0.75 KW ,length 2890MM

Equipped with a simple brush, blowing device, and preheating oven

heating:Infrared light tube, temperature adjustable;

Power:6.05kw.

Gluing System:

Heating power:2*0.75 kw(oil heating )

gluing roller:¢ 240*1400 silca 10mm 1pc

2stainless roller: ¢ 240*1400 silica roller thickness10mm

chrome roller: ¢ 216*1400 chrome 1pc

Black roller: ¢ 240*1400 1pc

Convyor roller 6pcs ¢ 80*1400 rollers 3pcs ¢ 120*1400

working width:1300 thickness:3-50 MM

speed:1-20meters overall size:2650*1380*2780MM

Control :PCL power2*1.5 kw+0.75 kw

Main power:36kw power of up and down: 0.37 kw

Lamiantion:

Working wodth:1300 thickness:3-50 MM

Working speed:1-20m lamiantion roller:¢240*1400 silica

control:PCL power:3 kw

power of up and down: 0.37 kw lamiantion roller: ¢ 240*1400 chrome

power of film hing :0.55 kw Magnetic powder brake:10 kgs

Inflatable shaft

Conveying Table:

Rollers are ø80 chrome

Coveying roller:dia ¢ 80*1400 stainess roller

power:0.75 KW ,length 2890MM

Price Term: In USD

Payment: 30 % deposit should be paid and 70 % balance should be paid after confirmation before loading.

Packing: Plastic film

Time of delivery: 15-20 days after confirmation of order

Installation: We will provide the installation service for the customer as requested. If the buyer request the seller to do the service in the seller's work place, the charge for applying visa, round tickets should be paid by the buyer as well as the food and hotel. USD100 per day should be paid for each technician’s salary. Machine is under one year guarantee.

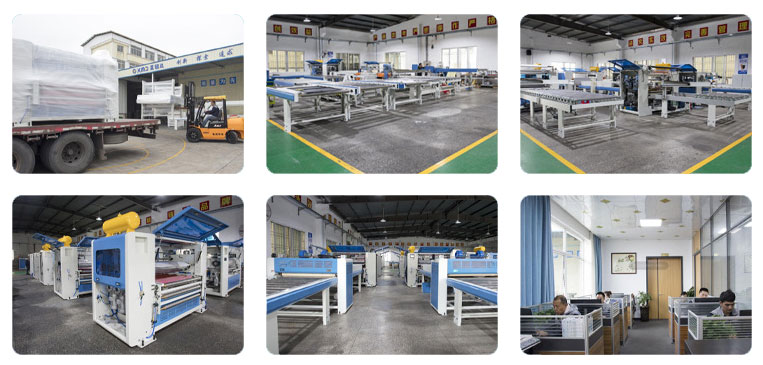

Factory Strenght

Foshan xingmingda automatic Woodworking machinery Co.,Ltd was founded in 2004, major in producing wrapping machines. Edege banding machines and slotting machines.Pur lamination machines.The company was located in Lunjiao Town, Shunde, Foshan. which is known as the famous town of woodworking machinery of china.It is a professional enterprise in design and producing hot-melt coating machine,wrapping machine,slotting machine hot glue wrapping machine, and cold glue wrapping machine ,PUR hot glue laminating machine etc.

We take technology and quality as the core of our tasks.Pursuit of customer’s satisfaction, struggle for strongest competitiveness.

In order to lasting spirit of fighting with “high-quality, High-efficient, innovation”,we adopted the advanced management system.

Qualification Certificate

Has been awarded ISO quality management system certification, AVIC quality management certification, as well as multiple utility model professional certificates, appearance design patent certificates, and invention patent certificates,

Exhibition Situation

FAQ

01.Are we a factory or a trading company?

We are manufactuer.

02.What Payment Methods Do You Accept?

Cash/TT/LC/DP...

03.Which countries do you sell your machine to?

China, USA, Australia, Poland, Russia, Uzbekistan, Turkey, Mexico, South Korea, Japan, North Korea, Egypt, Saudi Arabia, Iran, India, Pakistan, Malaysia,Singapore,Indonesia, Vietnam, Myanmar, Thailand, Kenya.etc.more than 30 countries.

04.Does it include installation and debugging?

We have export technican who can go to your factory to do testing.