600mm PUR Panel Wrapping Machine

Product Features

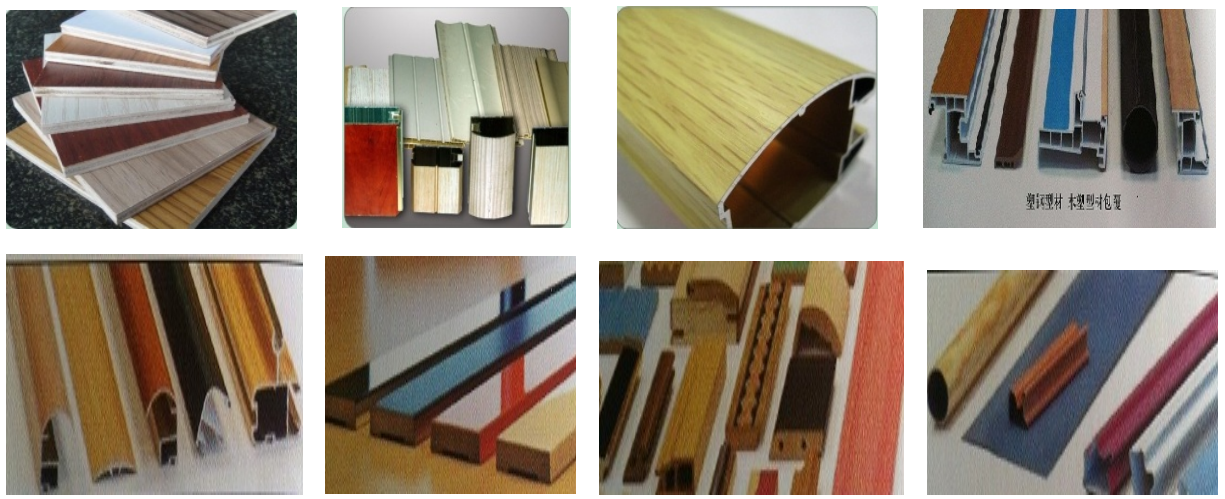

It can be applied to PVC and PVC plastic film. Using high standard glue, it can cover all kinds of angles, arc, concave convex surface, groove, curling, etc. Suitable for building materials, furniture, desktop, doors and windows, decorative strips or related professional manufacturers. Can be complex shape product surface to achieve perfect processing.

600mm PUR Panel Wrapping Machine can be applied to PVC and PVC plastic film. Using high standard glue, it can cover all kinds of angles, arc, concave convex surface, groove, curling, etc. Suitable for buiding materials, furniture,desktop, doors and Windows, decorative strips or related professional manufacturers. Can be complex shape product surface to achieve perfect processing.

| Max. film covering width | 620mm |

| Max. process thickness | 90mm |

| Min. process length | 600mm |

| Feeding speed | 1-35m/min |

| Feeding motor power | 2.2kw |

| Heating power | 22.5kw |

| Overall dimensions | 5000×1200×1800mm |

| Weight | 4000kg |

| Max width of cover film | 400mm |

| Max. diameter of roll cover material | 600/800/1200mm |

Reduce much space for more frames.

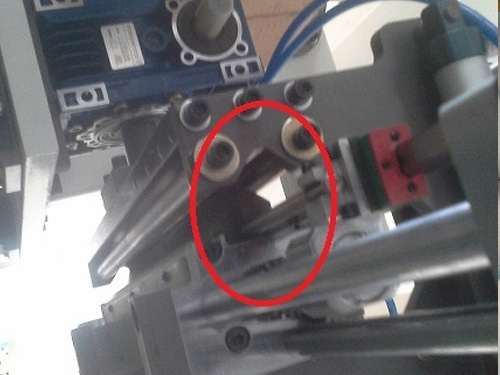

PUR part

1、pur glue box

Overall size:1600x1000x1850mm total 2950mm)

Pressure plate PUR melter consists of three parts: host, hose, hand / automatic glue gun. With the upper and lower temperature alarm, glue

Bit detection alarm and inverter alarm and other functions

1. Progressive heating and melting: the heating plate is located above glue system, when plate heating, only the top layer of glue and heating plate Contact, so that it reaches the melting point and melting, the next part of the barrel does not heat at this time, how much production, how much melted, to avoid long time heating and aging deterioration.

2. when the plastic glue and air isolation: heating plate and plastic bucket wall between the O-ring seal, making the molten liquid glue Quality will not contact with air, to meet PUR requirements.

3. Pressure plate with aluminum alloy casting, CNC precision machining, heating the outer surface of the plate by deep penetration sintering treatment, with Non-stick glue characteristics, the glue can easily remove, can effectively prevent the glue carbonization, to ensure the best gel, reduce the block of glue,

4.Stepless variable speed glue output adjustment; precision gear pump operation, using variable frequency inverter frequency control system. So as to control glue valumne.

5.the main motor running intelligent protection: When the heating plate temperature does not reach the lower limit temperature, the main motor can not run, so as to protect the machine.

6.plastic bucket emptying instructions: in the main cylinder with a sensor, when glue runs out, the alarm signal on.

2.Glue System:

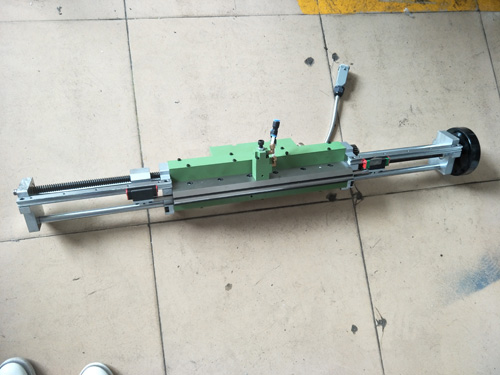

A. the glue system is made by:side board, automatic inflatable shaft, guide roller, roller cylinder, membrane, reducer, precision slide rail, precision Slider, precision screw rod, scraper system, button switch starter box, hole type magnetic powder brake, small motor, handle adjustment device etc.

B.operation principle of glue system: a set of PUR automatic glue glue system, maximum working width 1260MM, can quickly adjust the width of the most advanced two-way glue coating system, the width of digital display, glue system bracket can turn the adjusting +/-15 regulation.

C. laminating film installed on the inflatable shaft with automatic device,through film guide roller, coating device, scraper system, handle adjusting device, roller, and gluing device, feeding system,with an automatic electronic control gear pump for operation of gum at the same time, the coating production in time for changing speed, which can accurately control the glue supply operation, ensure the amount of glue, the glue supply device of coating system of uniform coating, no glue, no foaming, pile of rubber with good effect, to ensure that the surface is covered with high processing efficiency.

D.Roll film support, pneumatic tensioning coil feeding rack, can quickly change the film covering, can be quickly feeding regulation, scroll diameter 75MM,

Maximum coil diameter 600MM: Including: pneumatic brake and centering feed device.

E.Main configuration and technical parameters of gluing system;

Knife system:

The scraper system consists of a scraper holder, a scraper (refined from Japanese steel), a precise sliding guide, a precise slider, a precise screw rod, an oil-water filter, an electromagnetic valve, a pressure regulating valve and a reducer.

B.The operation principle of the scraper system is as follows: the scraper system is operated on the air expansion shaft of the automatic device with the rolling film-covered material, and the glue coating is completed by synchronous operation of the glue coating device, the feeding system, the scraper system and the glue feeding device of the automatic electronic control gear pump.

C. Main configuration and technical parameters of scraper system;

Material

7.Usage structure and Characteristic

(1)Usage

Our machines mainly use special pressure wheels to do wrapping for building materials with decorative lines ,PVC.CPL,etc.Which can cover various angles, circular, convex and concave surface and variety of different material,to make it more beautiful.mainly for decoration of hotels, restaurants, offices, families,and Villa etc.

(2)structure and Characteristic

Our machines are mainly composed of panel, paper supporting device, coating device, adhesive device, glue device,and electrical parts.

Product Application

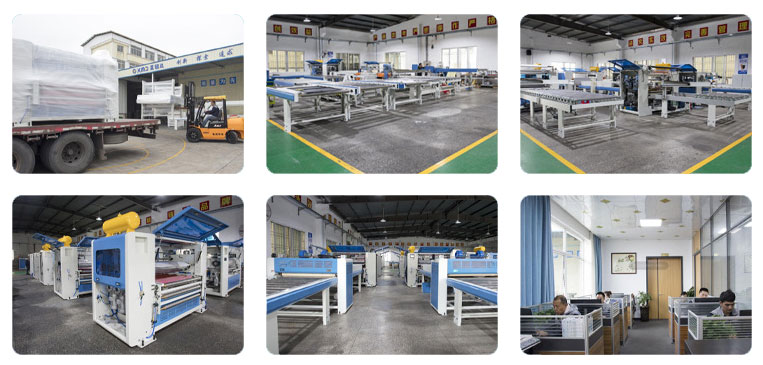

Factory Strenght

Foshan xingmingda automatic Woodworking machinery Co.,Ltd was founded in 2004, major in producing wrapping machines. Edege banding machines and slotting machines.Pur lamination machines.The company was located in Lunjiao Town, Shunde, Foshan. which is known as the famous town of woodworking machinery of china.It is a professional enterprise in design and producing hot-melt coating machine,wrapping machine,slotting machine hot glue wrapping machine, and cold glue wrapping machine ,PUR hot glue laminating machine etc.

We take technology and quality as the core of our tasks.Pursuit of customer’s satisfaction, struggle for strongest competitiveness.

in order to lasting spirit of fighting with “high-quality, High-efficient, innovation”,we adopted the advanced management system.

Qualification Certificate

Has been awarded ISO quality management system certification, AVIC quality management certification, as well as multiple utility model professional certificates, appearance design patent certificates, and invention patent certificates,

Exhibition Situation

FAQ

We are Manufactuer.

Cash/TT/LC/DP...

China, USA, Australia, Poland, Russia, Uzbekistan, Turkey, Mexico, South Korea, Japan, North Korea, Egypt, Saudi Arabia, Iran, India, Pakistan, Malaysia,Singapore,Indonesia, Vietnam, Myanmar, Thailand, Kenya.etc.more than 30 countries.