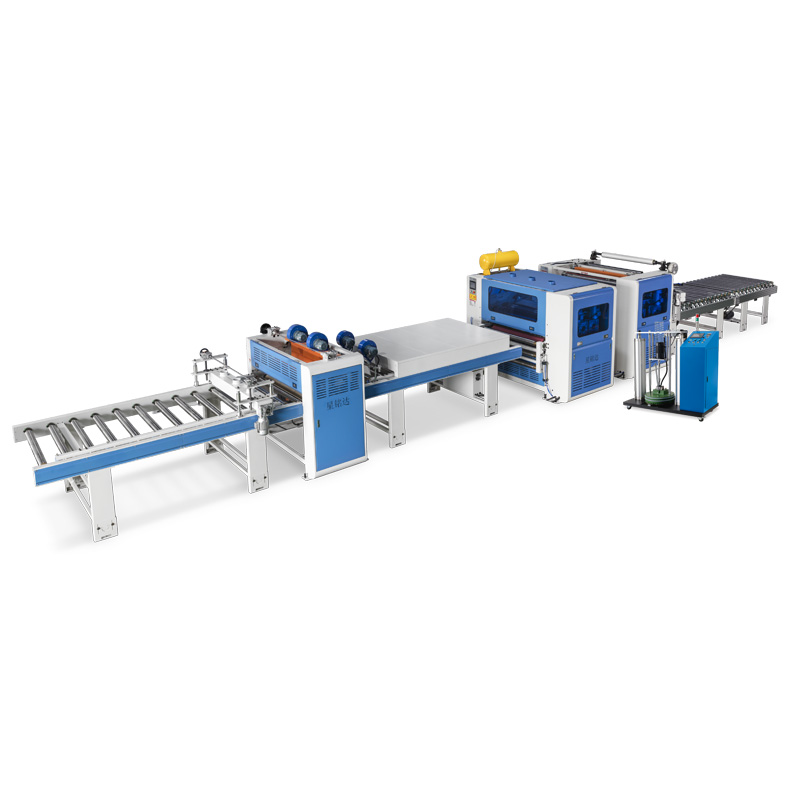

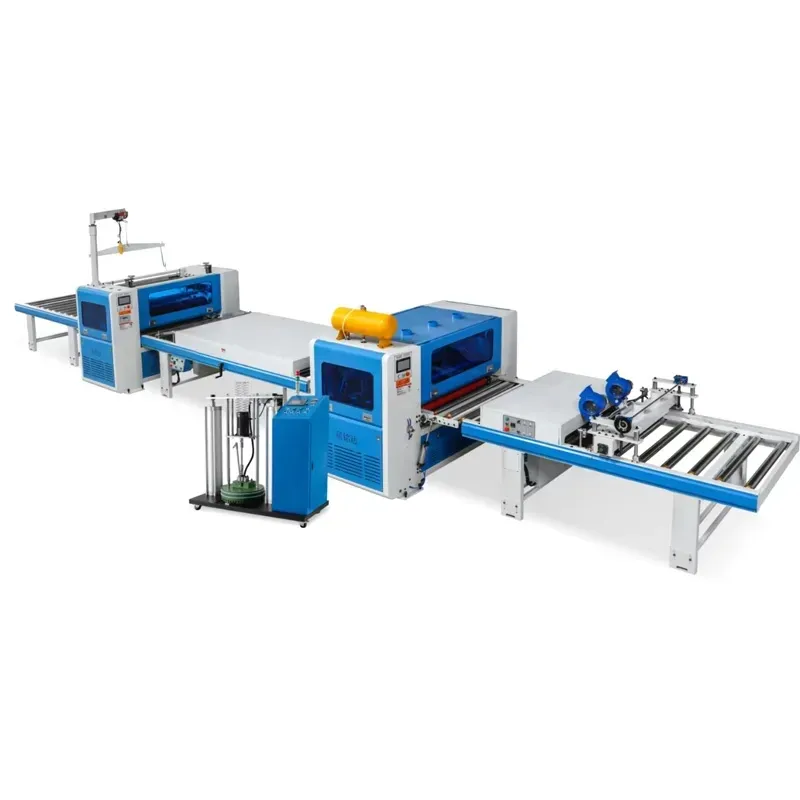

In the woodworking, furniture, and decorative materials industries, lamination equipment has quietly evolved from a supporting tool to a core productivity driver. As manufacturers shift toward higher efficiency and cleaner bonding technologies, machines such as the semi-automatic roll film lamination machine, roll film lamination machine, and full-scale PUR Lamination Machine line have become essential in modern production.

But while productivity and performance often take center stage, safety and proper operation are just as important—yet too often overlooked. At Foshan Xingmingda, we’ve seen many equipment failures traced not to hardware defects, but to improper operation or skipped maintenance routines. Today, we want to highlight a few practical, hands-on tips that can help operators avoid costly downtime and extend machine life—especially for systems in a PUR laminating production line.

Understanding the Hidden Risks Behind Lamination Equipment

Most operators are familiar with the basics: high temperatures, electrical wiring, hydraulic systems, and pressure devices must be handled with care. But everyday operation reveals more subtle risks—issues that don’t make loud warnings, but can cause major failures if ignored.

Below are essential yet often forgotten reminders for anyone working with a roll film lamination machine, semi-automatic roll film lamination machine, or full PUR Lamination Machinesetup.

1. Warm-Up Monitoring: A Step You Cannot Rush

Once the machine is heated and powered on, never jump directly into lamination.

Take a moment to confirm:

Temperature readings reach but do not exceed the calibrated range

Electrical current stays within expected load

No abnormal vibration or metallic resonance is heard

These checks are particularly important for a PUR Lamination Machine line, where high-temperature PUR glue must maintain stable viscosity to achieve uniform bonding.

2. Preventing Overload During Continuous Production

As production ramps up, both temperature and current fluctuate. That’s normal—within limits.

However, if the machine operates for long periods at maximum load, the following components become vulnerable:

Heating elements

Motors

Gear reducers

Transmission systems

During operation of a PUR laminating production line, stop periodically to check the readings. A two-minute inspection can save you a full day of maintenance later.

3. Synchronization Components: Small Part, Big Consequence

One easily ignored area is the screw on the coupling of the lifting synchronization rod—especially on gluing and laminating systems.

If it loosens, the rod may fall out of sync, causing:

Misalignment

Slide-seat damage

Lifter failure

Uneven film pressure

This applies to every model, from a semi-automatic roll film lamination machine to a larger roll film lamination machine or high-output PUR Lamination Machine line.

4. Proper Film Loading—A Routine Built on Precision

Incorrect loading not only wastes time and material—it creates safety hazards.

Always ensure:

The film roll is balanced

The tension is evenly set

Anti-wrinkle alignment is checked

The feed path is clean and unobstructed

A poorly loaded roll can instantly compromise the lamination quality of the entire PUR laminating production line.

Industry Analysis: Lamination Equipment Market Trends

| Category | Current Trend | Key Driver | Impact on Lamination Equipment |

|---|---|---|---|

| Demand for PUR Systems | Rapid Growth | Stronger adhesion, low VOC | Increased adoption of PUR Lamination Machine and PUR Lamination Machine line |

| Digital & Modular Manufacturing | Rising | Smart factory upgrades | Higher demand for semi-automatic roll film lamination machine with precise control |

| Eco-Friendly Materials | Expanding | Green regulations | Wider use of PUR adhesives and dust-free roll film lamination machine setups |

| Labor Shortage in Manufacturing | High | Skilled operator gap | More investment in automated PUR laminating production line |

| Furniture & Interior Market Recovery | Stable Growth | Home renovation boom | Increased demand for lamination in panels, profiles, and decorative surfaces |

FAQ

1. Why choose a PUR Lamination Machine over traditional glue systems?

PUR adhesive provides stronger bonding, higher resistance to heat and moisture, and better performance for high-end finishes.

2. How often should operators check temperature and current?

At warm-up, after the first 10 minutes of production, and every 30–60 minutes during continuous operation.

3. Does a semi-automatic roll film lamination machine require trained operators?

Yes. Even though semi-automatic systems simplify workflow, proper training ensures material consistency and machine safety.

4. What problems occur if synchronization rods loosen?

Misalignment that can lead to mechanical damage, uneven pressure, and unexpected shutdowns—especially in a PUR laminating production line.

5. How long can a PUR Lamination Machine line run continuously?

With proper monitoring, many systems can run 24 hours, but routine checks on heating, pressure, and current are essential.

Conclusion

Safe operation is not just about following rules—it’s about protecting your investment, your product quality, and your team. The semi-automatic roll film lamination machine, roll film lamination machine, and PUR Lamination Machine lineare powerful tools that deliver exceptional efficiency when operated with care and awareness.

At Foshan Xingmingda, we believe that the combination of advanced machinery and correct operation is the key to long-term success in modern woodworking and decorative production.

Ready to Upgrade Your Lamination Workflow?

📍 Website: purmachinefactory.com

📧 Email:pattypeng@purmachinefactory.com

Let’s build efficiency, safety, and high-quality lamination together.